In the field of construction, scaffolding plays a crucial role in providing a safe and stable working platform for personnel.

The selection of suitable scaffold materials is essential to ensuring the safety, efficiency, and cost-effectiveness of a project. This article will discuss five common scaffold materials, analyze their advantages and disadvantages, and explore their applications in different work scenarios.

By understanding this information, you will be better able to choose the appropriate scaffold materials for your project, ensuring smooth progress.

Bamboo

Bamboo scaffolding is a commonly used scaffolding structure in construction projects in various parts of Asia, especially in places like Hong Kong. It utilizes bamboo poles and bindings to create a sturdy framework for workers to access elevated areas.

Advantages

- High strength: Bamboo itself has good compressive and bending strength, allowing bamboo scaffolding to withstand significant weight and pressure.

- Low cost: Compared to materials like steel and aluminum alloy, bamboo is relatively inexpensive, resulting in lower costs for bamboo scaffolding.

Disadvantages

- Poor durability: Bamboo has limited durability and is susceptible to damage from weathering, pests, and human activities, resulting in a relatively short lifespan.

- Not suitable for tall buildings: Due to its limited strength and height, bamboo scaffolding is not suitable for erecting tall structures or supporting heavy loads.

- Flammable: Bamboo is highly flammable, posing a fire hazard.

- Safety: not comparable to steel and aluminum scaffolding

Applications

This type of scaffolding is only found in Asia and requires superb craftsmanship. Currently, this type of scaffolding is becoming less and less common.

Wood

Wooden scaffolding is a type of scaffold that uses wood or wooden components as the main material. This type of scaffold is mainly used in construction to provide a safe and stable working platform for workers to complete their tasks.

Advantages

- Environmental friendly: Wood is a renewable resource, and using wooden scaffolding is beneficial for the environment.

- Low cost: Wood is relatively cheaper compared to other materials, which helps to reduce the cost of scaffolding.

- Easy to transport: Wooden components are relatively lightweight, making them easy to transport and convenient for assembly and disassembly.

Disadvantages

- Fire hazard: Wood is flammable, posing a fire risk at construction sites. Therefore, additional preventive measures and fire safety precautions must be taken.

- Susceptible to moisture: Wood is prone to moisture absorption, which can lead to deformation or cracking with prolonged use.

- Limited load-bearing capacity.

Attention:

Both wooden and bamboo scaffolding are relatively old for modern construction, and we don’t recommend either from a safety or other point of view.

Steel

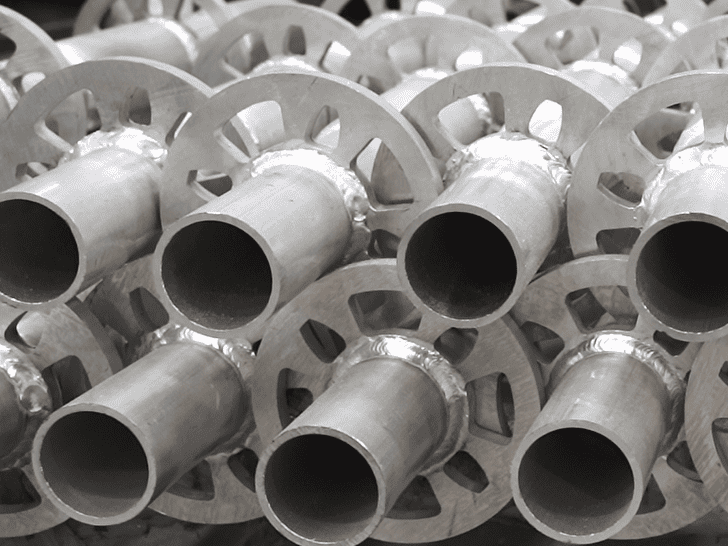

Steel scaffolding is the most commonly used scaffolding, mainly made of high-strength steel such as Q235, Q355, etc. These steels have the advantages of high strength, strong load-bearing capacity, and good stability, making them suitable for construction environments with high requirements for load-bearing capacity and stability, such as high-rise buildings and large bridges.

Advantages

- High strength, strong load-bearing capacity: Steel has high strength and load-bearing capacity, able to withstand heavy loads and ensure construction safety.

- Good stability: The structure of steel scaffolding is stable, providing good support and not easily deformed or shaken.

- Reusable: Due to the plasticity and strength of steel, steel scaffolding can be disassembled and reused, reducing costs.

- High safety: Steel is not easily combustible, improving construction safety.

Disadvantages

- High cost: Steel is a relatively expensive material, so the cost of steel scaffolding is relatively high.

- Heavy weight: Steel has a high density, resulting in heavy weight of steel scaffolding, which is not conducive to transportation and handling.

- High maintenance requirements: Although there is surface treatment, steel itself is not corrosion-resistant. After multiple uses, there is a possibility of rusting, requiring regular maintenance and rust prevention treatment.

Applications

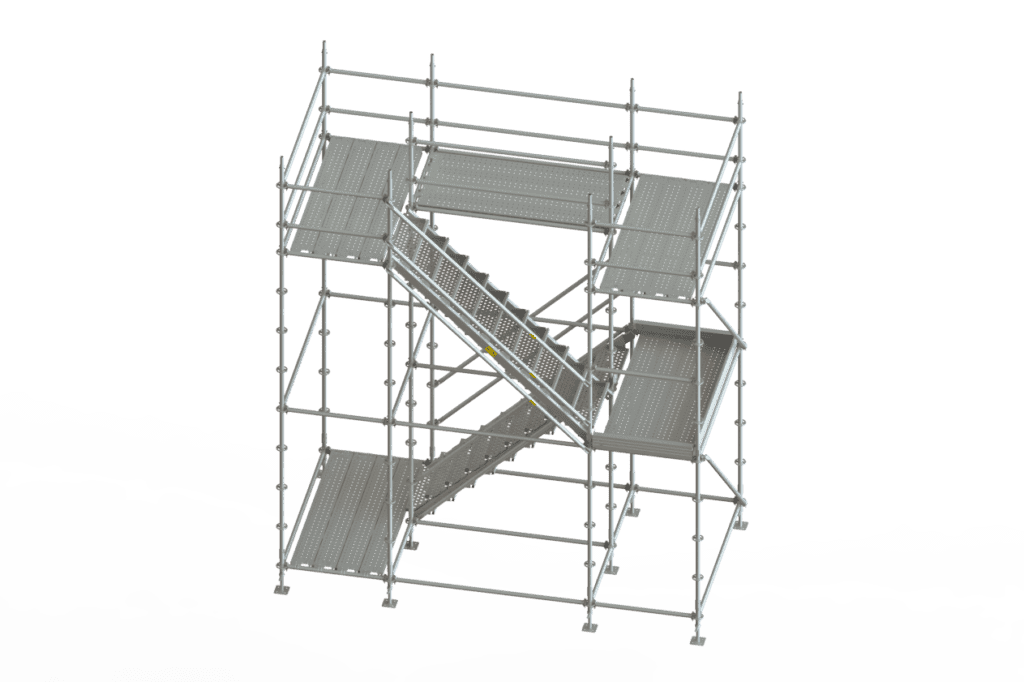

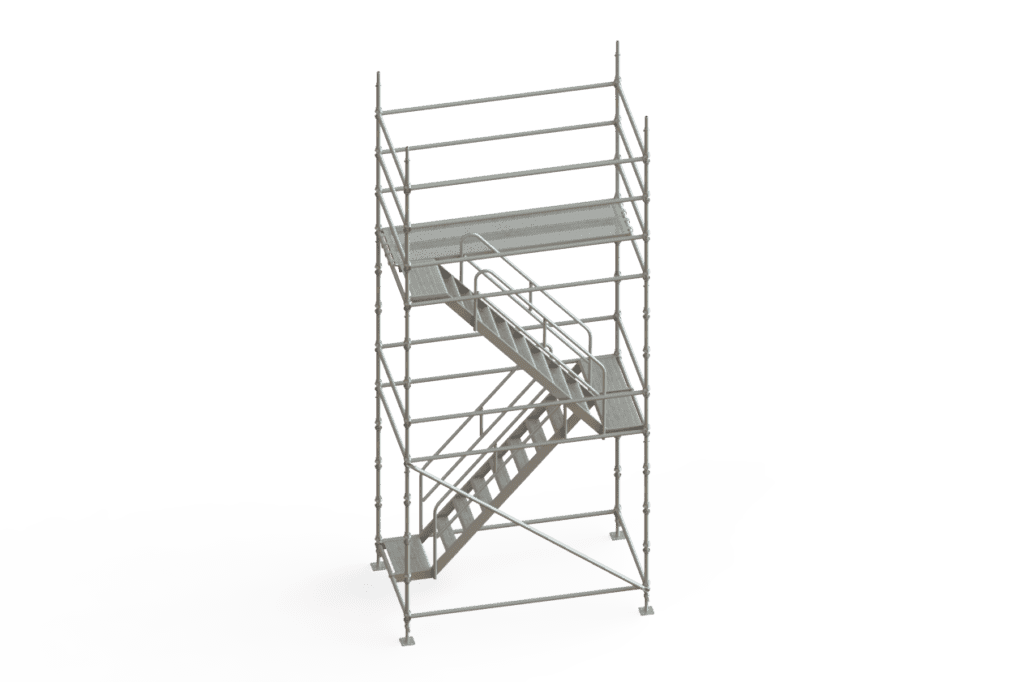

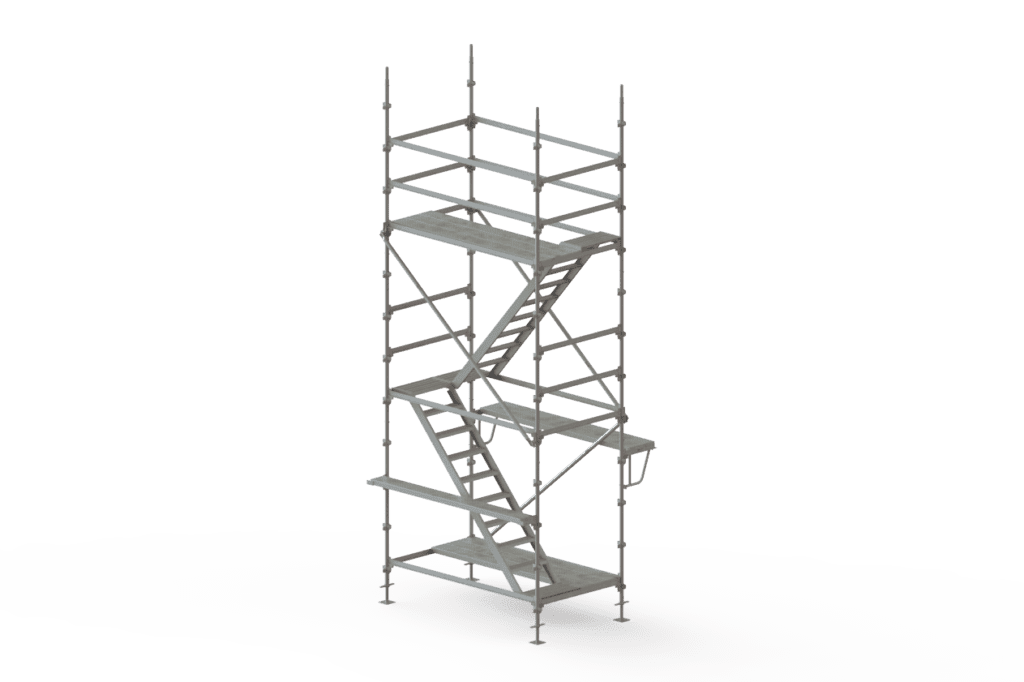

Common steel scaffolding is ringlock scaffolding, cuplock scaffolding, kwikstage scaffolding, etc. They are all modular scaffolding, with the features of quick loading and unloading, labor-saving, stable and reliable structure, and so on. They are widely used in houses, bridges, tunnels, chimneys, water towers, bridges, factories, elevated water towers and other construction facilities.

Aluminum

Aluminum scaffolding is usually made from 6061-T6 or 6082-T6 aluminum alloy materials. These alloys have good strength, plasticity, and toughness, which can meet the load requirements of scaffolding while maintaining a lightweight design. They are 75% lighter than traditional steel scaffolding, making them convenient for transportation and installation.

Advantages

- Lightweight: Aluminum alloy scaffolding is lighter than steel scaffolding because aluminum alloy has a lower density than steel. This means that aluminum alloy scaffolding is lighter in weight, making it easier to transport and handle, and reducing labor and material costs.

- Corrosion resistance: Due to the special material properties, aluminum alloy scaffolding has natural corrosion resistance.

- Versatility: Suitable for various tasks with different work intensities, both indoors and outdoors.

- Easy and quick installation: Aluminum alloy scaffolding can be quickly assembled and disassembled without relying on professional skills or complex tools, greatly improving construction efficiency.

Disadvantages

- Cost: its price is relatively high, so the cost of aluminum alloy scaffolding is also relatively high. In comparison, wood and steel are more common and have lower costs, so in some cases, using wood or steel as the material for scaffolding may be more economical.

- Load capacity: Aluminum alloy scaffolding cannot withstand the same weight as steel scaffolding. In comparison, steel scaffolding has a higher load capacity and can bear heavier weights.

Applications

Aluminum scaffolding is an indispensable tool in building construction, providing a stable working platform for workers to facilitate their overhead work, such as beams and columns installation, concrete pouring, and wall construction. Common aluminium scaffolding are alu ringlock scaffolding, alu kwikstage scaffolding, alu scaffold tower, etc.

Fiberglass

Fiberglass is a high-performance composite material made of glass fibers and organic polymers. It can be used to manufacture various fiberglass reinforced plastic (GFRP) products, such as fiberglass reinforced pipes.

Although the application of this material in the scaffolding industry is relatively new, its excellent performance makes it very advantageous in some specific applications. For example, fiberglass reinforced pipes can be used to manufacture lightweight, high-strength, and corrosion-resistant scaffolding pipes. These scaffolding pipes have good mechanical and electrical properties, can withstand high pressure and bending, and are not prone to rust and chemical corrosion.

Advantages

- Lightweight: Fiberglass is lighter than aluminum, making it easier to transport, assemble, and dismantle. This is particularly beneficial for projects with restricted access or weight limitations.

- Excellent corrosion resistance: Unlike aluminum, fiberglass has strong corrosion resistance, even in harsh environments such as saltwater or chemical exposure. This eliminates the need for painting or special coatings, reducing maintenance costs and extending the lifespan of the scaffolding.

- Outstanding electrical insulation performance: Fiberglass is a non-conductive material, making it ideal for working near electrical hazards. This eliminates the risk of electric shock, improves safety, and ensures compliance with regulations.

Disadvantages

- Higher initial cost: The upfront cost of fiberglass scaffolding is usually higher than aluminum scaffolding.

- Limited availability: Although fiberglass scaffolding is becoming more common, it is not as readily available in some areas as aluminum scaffolding.

- Susceptibility to UV Damage: While FRP materials are generally durable, some FRP materials may deteriorate with prolonged exposure to UV radiation.

- Specific installation techniques: Compared to aluminium scaffolding, FRP scaffolding may require specialised installation techniques and tools.

Conclusion

Whatever scaffolding material you choose, you need to consider your budget, project requirements, safety, etc. APAC Scaffold as a professional scaffolding manufacturer and supplier, is ready to provide you with the most professional advice to help you make an informed choice. If you still have questions, please feel free to contact us!