products

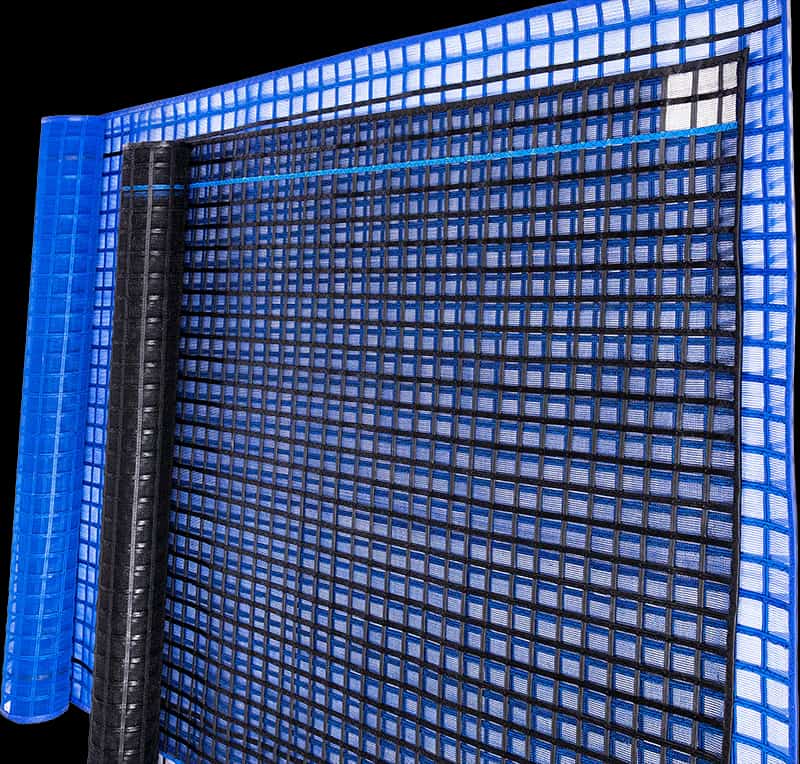

Fire Retardant Containment Mesh

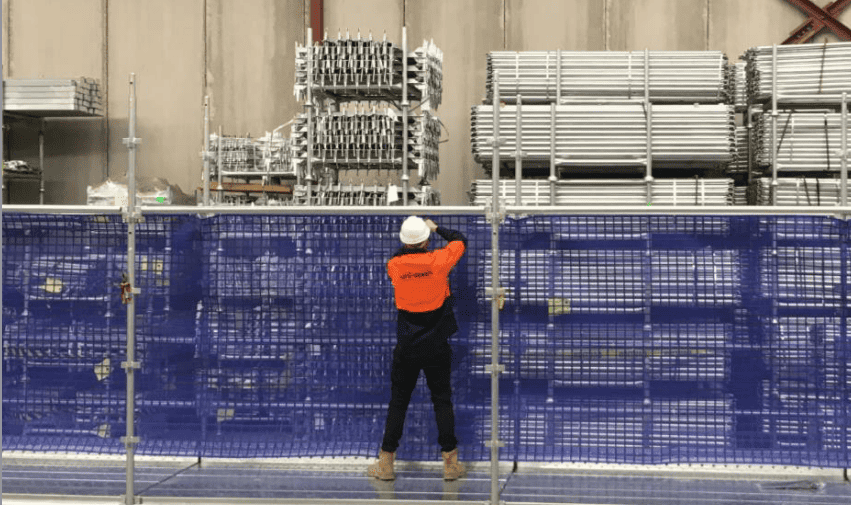

The fire retardant containment mesh is a specially designed system that effectively encloses scaffolding from the inside, ensuring the safety of workers at height. Its primary purpose is to prevent any objects from falling off the scaffolding, thus minimizing the risk of potential injuries and property damage.

- Highly durable

- Easy to use

- Fire resistance materials are also available

- Easy storage – rolls up after use

BENEFITS

Use Fire Retardant Containment Mesh to Work Smart

- Significant saving in labor installation and dismantle times

- Wire is eliminated completely with no wire tangles or potential lacerations – Reduction of trip hazards

- Decreased product weight compared to traditional chain and shade systems

- Can be re-used multiple times (Prior to re-use, all mesh rolls to be checked for structural integrity)

- Can be cut and shaped easily

APPLICATIONS

The Applications of the Fire Retardant Containment Mesh

The fire retardant containment mesh has become an indispensable material in the construction industry. It not only prevents fires from spreading, but also provides many other benefits. It provides good protection against debris and dust generated during the construction process, keeping workers safe and maintaining a clean working environment. FRC-Mesh is durable and lasting, making it a cost-effective solution for construction sites. It is also easy to install and dismantle, providing flexibility for contractors.

Installation & Uninstallation

- Position the roll upright.

- Attach the FRC-mesh to at least three points of contact to ensure the remainder of the installation is fast and efficient.

- Once the three points of contact are affixed, begin to roll out the FRC-mesh to the halfway point of the bay. Affix FRC-mesh to the top rail with one tie.

- Continue rolling the FRC-mesh out to the next standard. The user will again affix the FRC-mesh with three fixtures.

- Affix the remainder of the FRC-mesh to the inside of the scaffold structure.

- Continue rolling out the FRC-mesh and follow steps 1 – 5 again to complete the job.

- Remove ALL fixtures except the ones on the top rail.

- Once all but the top ties are removed, you can begin to roll up the product with one person.

- Roll the product up to the next tie and remove that tie to continue rolling up the FRC-mesh, this will ensure the roll is tight and easily transported.

- It is recommended to use your foot to brace the FRC-mesh to ensure conformity of the roll. When you have reached the next tie, it can now be removed.

- Continue this process until you reach the end of the roll.

- Once the last tie has been removed, you can secure the roll by using zip ties or tie-wire.

Movement & Storage

- FRC-Mesh is light enough to be carried by one worker.

- If a scaffold strip is in progress, FRC-Mesh must be passed, craned or lowered down.

- Under no circumstance should it be dropped from height to prevent damage.

- FRC-Mesh must not be dragged along the ground to prevent the shade cloth from tearing.

- It is recommended that FRC-Mesh is rolled up and stored in pallets/stillages and kept out of the sun to prevent UV damage of the plastic.

- It is not to be stored flat, creased or squashed.

- It is a natural characteristic of plastic to degrade and fade when exposed to the sun for an extended period of time.

- In order to enhance the lifespan of the product, undercover storage is recommended when FRC-mesh is not in use.

We are Fire Retardant Containment Mesh Supplier

Types of Fire Retardant Containment

- APAC can supply you the Fire Retardant Containment Uni- mesh in blue, black, beige and red colors.

- You can also contact us for customization.

Manufacturing Processes

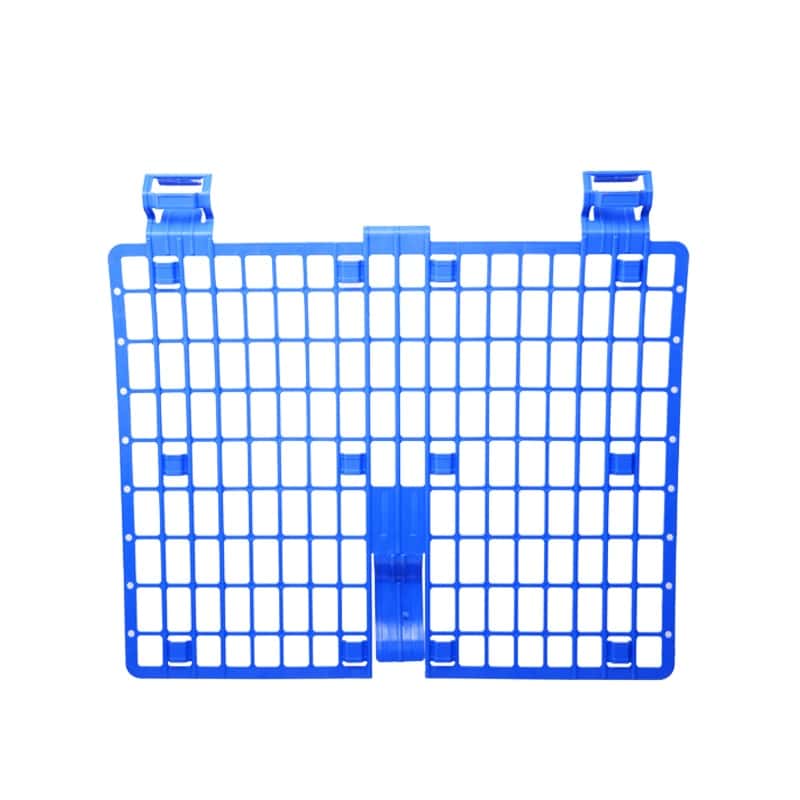

- We strictly combine the woven mesh and the steel-plastic grid of strips by means of ultrasonic welding technology. The steel- plastic grid of strips are on both sides and the woven mesh(debris net) is in the middle of the strips, welded together them to one piece.

- Each steel-plastic grid strip contains 6 wires, this design makes the Fire Retardant Containment Uni-mesh stronger and more durable than traditional scaffolding debris net

- Save your time, cost and labour with APAC’s Fire Retardant Containment Uni-mesh, which looks great after installation. It is the perfect choice for fall protection on scaffold work platforms.

Why Choose Us

- APAC has been manufacturing and supplying Scaffolding Fire Retardant Containment Uni-Mesh system to accommodate scaffolding for more than ten years.

- The Scaffolding Fire Retardant Containment Uni-Mesh series products fully comply with WHS regulations and Australian standards AS 1530.2-1993.

- Our company has successfully launched multiple edge protection systems suitable for a wide range of construction site needs.Our products have been exported to more than 30 countries. Such as the US / UK / Canada / Australia / New Zealand / UAE / Malaysia / Singapore etc.

Yes, Scaffold Net is reusable. When you install the products the first time, you don't need to use destructive procedures. Attaching them with tie clips is sufficient to achieve the target strength. So, you can quickly disassemble the mesh from a previous installation by removing the earlier clips and avoiding any significant damage. Small perforations during the previous installation do not affect the quality. These meshes are ready to be reused at other sites and you don't need to replace them with new ones. For reuse, follow the same steps following the installation the first time.

When rolling up the fireproof net, it should be securely fixed with tape, rope, or another fastening method and then wrapped in plastic film. Finally, firmly seal the plastic outer packaging with tape. You may also specify alternative packing methods.

We strictly control quality in every working procedure according to ISO:9001 quality management system. Welcome to visit our factory to know more about us.

Always a pre-production sample before mass production.

Always final inspection before shipment.

T/T % in advance & T/T upon sending the copy of Bill of Lading, L/ C , or negotiate according to the order status.

Yes, we require all international orders to have a minimum order(MOQ) quantity.Orders less than MOQ are not cost effective due to the combined costs of shipping costs and duties. We recommend you to buy from our local distributor.