- 388 Dongwu South Road, Suzhou City, P.R.China

- info@apacscaffold.com

- 0086-512-66700084

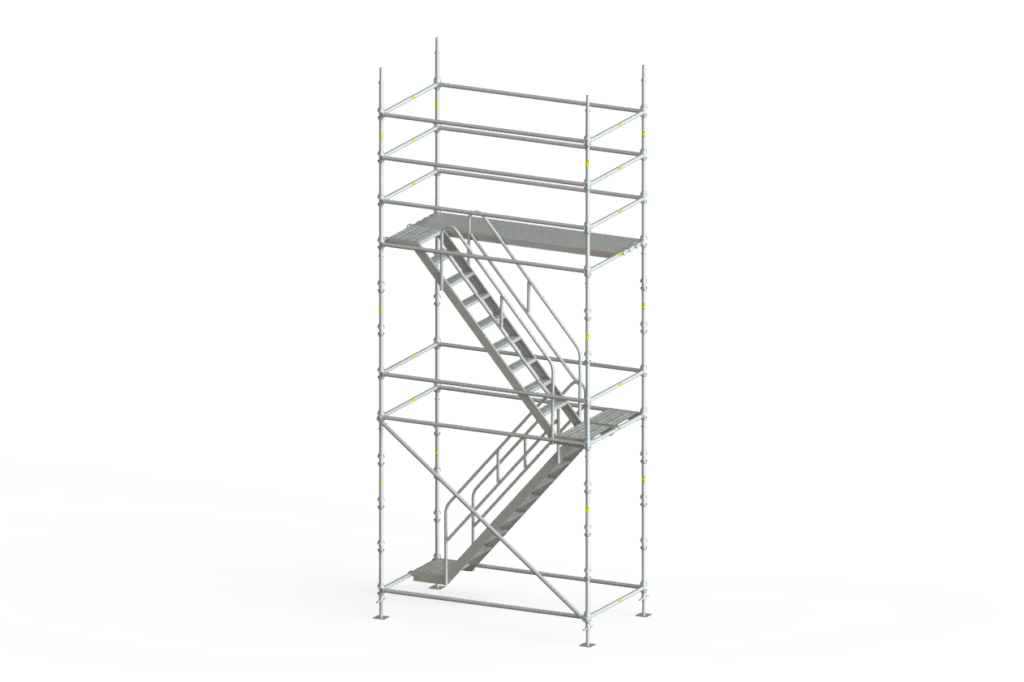

Cuplock scaffolding is a type of scaffolding that uses metal cups to lock the crossbeams together. This type of scaffolding is temporary and is mainly used in construction or renovation work to provide a safe working platform for workers.

Verticals provide the vertical support for scaffolding. Distance between two cups 500mm, Top cup drop forged and Bottom cup pressed.

Used for the lateral bracing cuplock scaffolding. The braces can also be used as obtuse angle mid rail and top or hand guard rails in conjunction with our stair system

A frame plank is designed to span the bay by hooking to the horizontal members of the bay, providing a safe work platform. Hot-dipped galvanized surface finish.

The cuplock scaffolding side bracket is used to extend the scaffold platform by cantilevering for additional decks. Length can be customized.

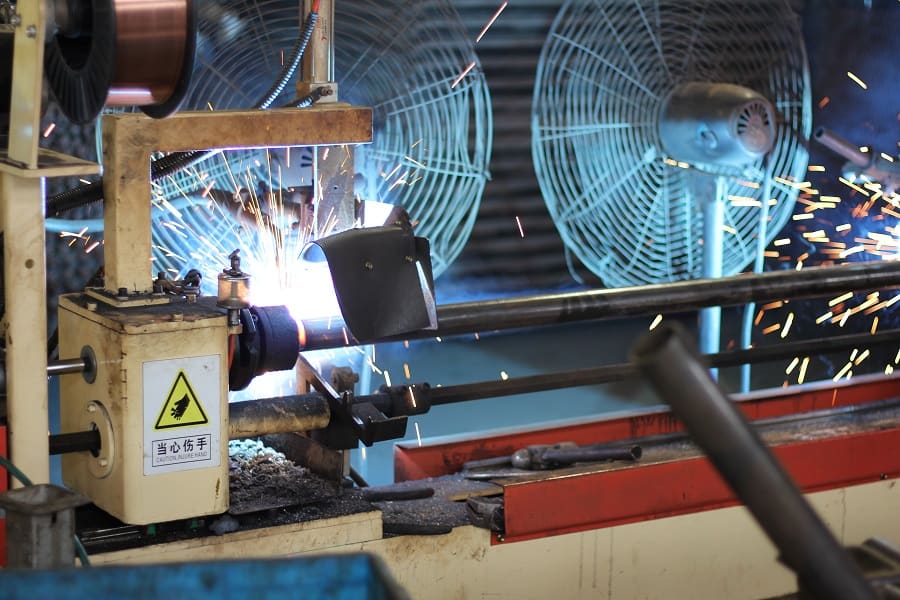

We offer factory-direct scaffolding, which means you can buy high-quality, competitively priced products directly from our factory.

Through factory direct sales, we are able to better control the quality and delivery time of our products to ensure that you can get the products you need in time. With our complete production facilities and professional production team, we can respond to your needs quickly.

If you are interested in our scaffolding or have any questions, please feel free to contact us. We will be happy to serve you and look forward to cooperating with you.

We are committed to providing our customers with a wide range of surface treatments to meet their different needs and customization options. The surface treatments we offer include hot-dip galvanizing and powder-coating, which can effectively improve the service life and aesthetics of the scaffolding.

If you have special needs or specific requirements for colors or logos, we can also customize the finish to meet your individual needs.

Our quality control includes pre-production, in-production, and post-production stages, aiming to ensure that every aspect of our scaffolding, from raw materials to finished products, is under strict control.

During the production process, our quality inspection team will carry out full supervision to ensure that each process meets quality standards. Before the products leave the factory, we will carry out a comprehensive quality inspection to ensure that the products meet the needs of customers and industry standards. At the same time, we also accept inspections from third-party quality inspection organizations to ensure product quality more objectively and fairly.

WhatsApp us