Most of the building construction projects are working on scaffolding, but every year there are scaffolding safety accidents, in order to effectively avoid or reduce the occurrence of such accidents, we usually recommend that construction sites use scaffolding tags, so that the workers first time to understand the status of the use of scaffolding.

In this article, we will do a comprehensive introduction to scaffolding tags.

What are Scaffold Tags?

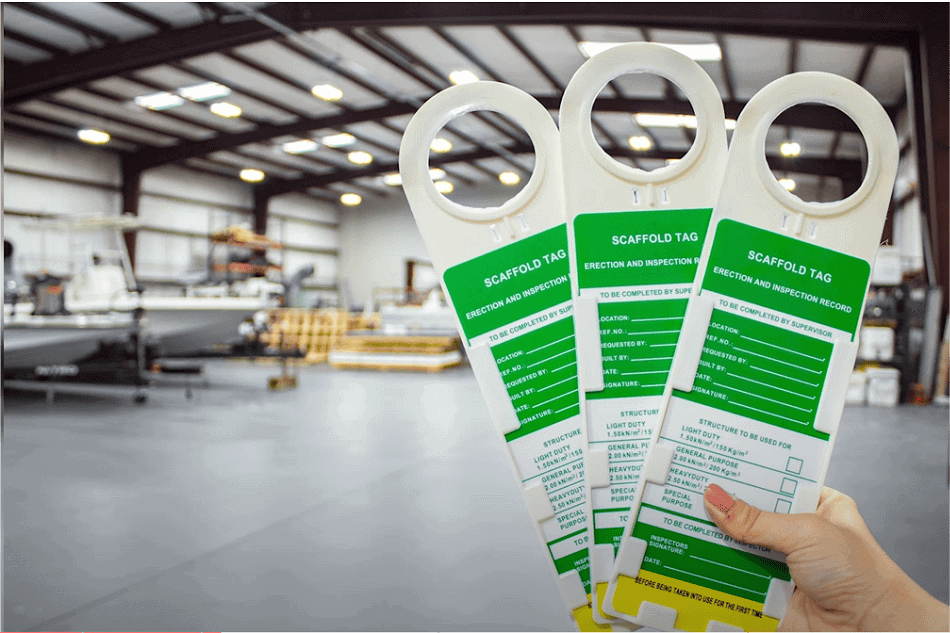

Scaffold tags are signage hung on scaffolds that provide information about scaffold safety and inspections, making it easy for crews to keep up to date with the status of scaffold use, and are one of the most important tools for keeping construction sites safe.

Different Types of Scaffolding Tags

There are three main types of scaffolding tags, each with its own meaning and significance, and they help workers and all those involved make the right choices. The scaffolding tag system usually has the following color schemes: green, yellow, and red.

Green Scaffolding Tag: Available for use

Green scaffolding tags usually signify “OK” and can be used. Hanging a green tag on scaffolding is like obtaining a safety clearance, indicating that the scaffolding has undergone rigorous inspection, meets all safety standards, and can be used with confidence.

Yellow Scaffolding Tag – Keep Caution

The frequency of using yellow scaffolding tags is relatively low, representing modifications to the scaffolding that make it difficult to meet current job requirements. Workers should “be cautious and follow specific safety requirements” when working. The yellow scaffolding tag should indicate:

- Potential hazards

- Precautionary measures to be taken before use to mitigate risks

- The name of the authorized unit using the scaffold

Note: After completing the inspection of the scaffolding and confirming that it is in a usable state, the scaffolding tag should be promptly replaced with a green one.

Red Scaffolding Tag – Danger

Red, being an eye-catching colour, attracts attention quickly. A red tag on scaffolding means that the scaffolding is not yet complete or that there are safety hazards that require people to take extra care. The red scaffolding tag comes as a complement to and completes the green and yellow tags, which are more direct.

Scaffolding Tags Requirements

The Occupational Safety and Health Administration (OSHA) has developed scaffold safety guidelines and requirements. Although there are no specific requirements for scaffolding tags, 29 CFR 1926.200(h)(1) contains a provision that mandates placing warning tags on any existing hazards (such as defective tools or equipment). Partially erected scaffolding may lack guardrails or ladders and must be properly tied off or completely planked.

Key information that must be included on scaffolding tags to accurately convey the scaffold’s safety status:

Tracking Code: Each scaffolding tag should have a unique identification number or code for identification and tracking purposes.

Inspection Date: The date of the most recent inspection of the scaffolding should be prominently displayed on the tag. This ensures that workers are aware of when the scaffold was last safety assessed.

Personnel name: Include information on inspector/installer/maintainer/dismantler for easy retrieval when needed.

Inspection Results: Any findings or observations from the inspection should be documented on the tag. This includes recording any defects found, necessary repairs, or other preventive measures to be taken.

Where should scaffold tags be placed on the scaffold?

Scaffolding tags should be placed in specific locations on the scaffolding to meet certain requirements:

Ease of Reference: Tags should be placed in conspicuous positions, easily visible for workers to check safety indicators at any time. These locations should be accessible and unobstructed for workers to approach and read without interference from other objects.

Non-interference with Construction: The positioning of tags should not hinder the normal operations of construction workers or the movement of materials and equipment. Therefore, tags should be avoided in areas where construction workers frequently pass through or need to operate.

Specifically, tags can be placed in the following locations:

Scaffolding Entrances: These are essential pathways for construction workers to enter the scaffolding, making it crucial to place tags to remind them of safety precautions.

Work Platforms: Setting tags on work platforms can remind construction workers to pay attention to safe operations, especially for tasks like working at heights.

Near Ladder Access Points: Ladders serve as access points for ascending and descending the scaffolding, and warning signs should be placed nearby to remind people to use them carefully and take necessary safety measures.

Overall, the choice of scaffolding tag placement should prioritize the effectiveness of safety indicators, ensuring they are easily visible for workers while not impeding construction activities. Additionally, for standardization purposes, construction sites should establish uniform positions for tag placement to ensure that every scaffolding structure has the appropriate safety signage, maintaining consistency in direction, size, and other factors.

How often should scaffolding be marked?

Although the specific frequency of tagging may vary depending on site regulations and actual conditions, it’s generally recommended to inspect and re-tag scaffolding at least once a week. Especially in adverse weather conditions, the frequency of inspection and re-tagging may be higher to ensure the safe use of scaffolding.

Furthermore, every time structural modifications or repairs are made to the scaffolding, it should be re-tagged to reflect its latest safety status.

Benefits of Using Scaffolding Tags

Clear Safety Status:

Scaffolding tags provide a visual representation of the scaffolding’s safety status. This allows construction workers to understand the scaffold’s safety condition immediately and make correct operational decisions.

Enhanced Safety Awareness and Accident Prevention:

The text and graphics on the tags can remind construction workers to pay attention to safety, reinforcing their safety awareness. Through continuous reminders and alerts, construction workers will pay more attention to safe operations, reducing the occurrence of accidents.

Increased Efficiency and Productivity:

With clear tag instructions, construction workers can quickly find the scaffolding suitable for their work, reducing unnecessary inspection time. Additionally, the use of tags can reduce safety accidents caused by misunderstandings or communication barriers, thereby improving work efficiency.

Promotion of Standardized Management:

Using standardized scaffolding tags helps promote standardized management at construction sites. The consistent use of tags ensures that each scaffold has the appropriate safety signage, facilitating unified management and inspection by management personnel.

Simplified Inspection and Maintenance Processes:

Scaffolding inspection tags simplify inspection and maintenance processes by providing a standardized method for evaluating scaffold safety. Inspection personnel can easily identify and assess scaffolding based on the information displayed on the tags, ensuring thorough inspection and timely maintenance to address any safety issues.

Conclusion

Using scaffolding tags is of great significance for enhancing construction site safety, promoting standardized management, improving work efficiency, and clarifying legal responsibilities.

Therefore, in the construction process, sufficient attention should be paid to the use of scaffolding tags to ensure that each scaffold has clear safety signage.