Introduction

In today’s competitive construction environment, speed, safety, and adaptability are paramount. That’s where Cuplock scaffolding comes in. Whether you’re building high-rise towers in urban centers or restoring delicate historical structures, Cuplock offers a reliable, modular solution trusted by contractors across Asia, the Middle East, and beyond.

This guide offers an in-depth look into Cuplock scaffolding systems—breaking down how they work, the advantages they offer over traditional systems, and why they’re considered the gold standard for demanding job sites.

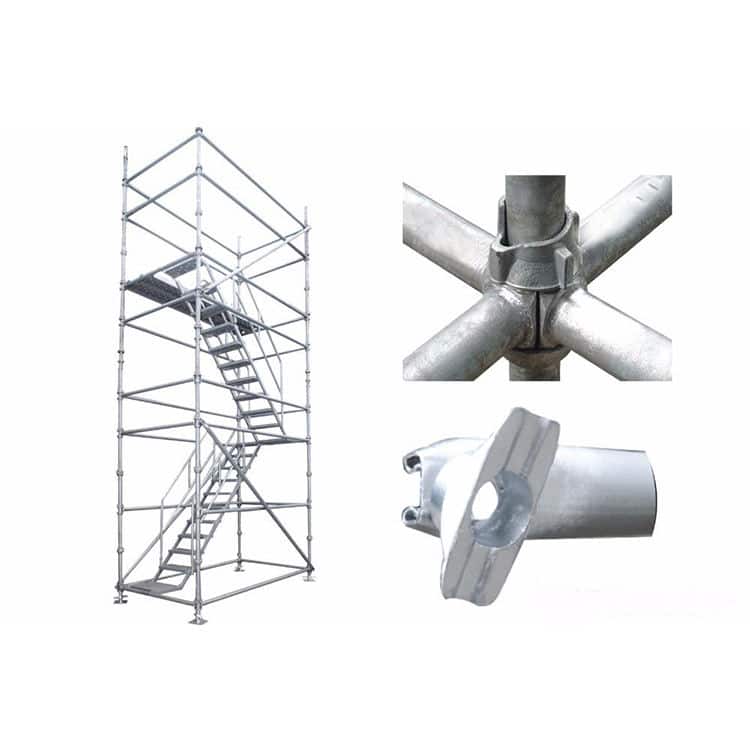

What is Cuplock Scaffolding?

Cuplock scaffolding is a type of modular system that connects horizontal and vertical steel components using a patented cup-and-blade locking mechanism. Vertical standards feature fixed lower cups welded at 0.5-meter intervals, with movable top cups that lock the horizontal ledgers into place. Once locked with a hammer strike, the connection is secure without the need for bolts, clips, or wedges.

This method provides faster, tool-free assembly and consistent alignment across all levels. The uniform design minimizes errors, boosts site productivity, and ensures safety across complex structures.

Cuplock Components

- Vertical Standards

These form the vertical framework of the scaffold and are equipped with cup joints at half-meter intervals. Each node point can accommodate up to four horizontal connections. Standards also include a spigot and lock pin for vertical stacking, offering height flexibility. - Horizontal Ledgers and Transoms

Ledgers connect horizontally across standards and help distribute loads evenly. Transoms provide intermediate support for scaffold boards. Both components are made from galvanized steel and feature forged blades that slot into the cup joints easily.

- Universal Jacks and Base Plates

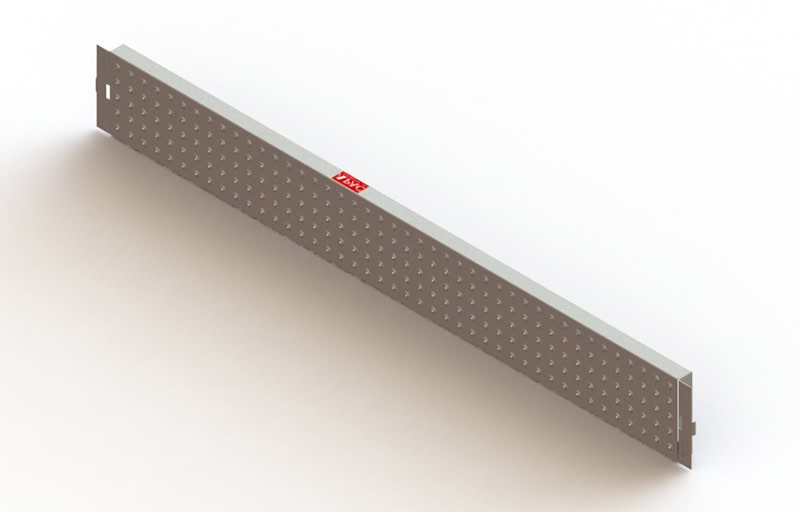

These components form the base of the scaffold, allowing for adjustments on uneven terrain. Jacks offer fine-tuned height leveling, while base plates spread loads to ensure a stable foundation. - Intermediate Transoms

Installed between ledgers, intermediate transoms offer extra support for scaffold planks. Their jawed ends and locking mechanisms prevent movement, enhancing platform safety.

- Hop-Up Brackets

These brackets extend the scaffold platform outward, typically supporting two or three additional boards. This feature is especially useful for wider work areas and allows for guardrail integration at extended sections. - Beam Brackets and Cantilever Frames

Ideal for creating projections or supporting platforms beyond the main structure. These allow for complex scaffold designs such as loading bays and walkways around obstructions.

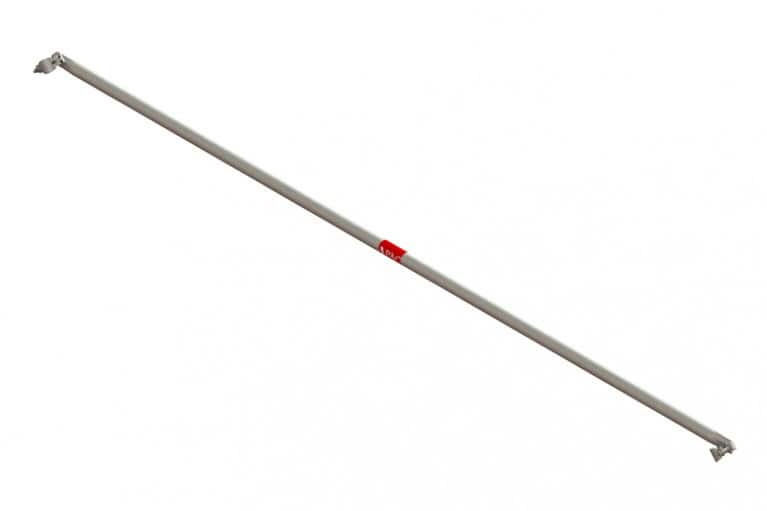

- Diagonal Braces and Toe Boards

Diagonals improve the scaffold’s lateral stability and are installed across bays to prevent sway. Toe boards are used at the edge of platforms to prevent tools or materials from falling.

Why Cuplock Scaffolding Outperforms Traditional Systems

Faster Installation and Dismantling

Cuplock’s cup-node connection system allows multiple horizontal members to be secured simultaneously. With fewer components and no loose parts, scaffold erection becomes faster and less error-prone.

Stronger, Lighter Materials

Components are hot-dip galvanized, making them rust-resistant and durable for long-term use. The design also eliminates the need for bulky bracing, reducing weight without sacrificing strength.

Improved Safety

Unlike traditional scaffolding with tube-and-coupler systems that can loosen over time, Cuplock’s rigid connections minimize movement. Platforms can be extended seamlessly with hop-up brackets, providing uninterrupted walkways that reduce trip hazards.

Minimal Maintenance

Fewer moving parts mean fewer things can go wrong. With proper storage and cleaning, Cuplock scaffolding components maintain their integrity for many years.

Where Is Cuplock Used?

Building Construction

From residential high-rises in Mumbai to commercial developments in Dubai, Cuplock scaffolding’s flexibility makes it suitable for nearly all structural types. It adapts quickly to building layouts, including angled or circular designs.

Infrastructure Projects

Cuplock scaffolding has been used extensively in major infrastructure efforts like metro rail extensions, flyovers, and bridge construction. Its ability to support heavy loads and its adaptable configuration are invaluable for such complex work.

Industrial Maintenance

Facilities like oil refineries, chemical plants, and factories frequently use Cuplock systems for maintenance access. Their robust design and galvanized protection make them ideal for corrosive or high-heat environments.

Shipbuilding and Marine Applications

Thanks to their corrosion-resistant coating and stability, Cuplock scaffolds are used for hull maintenance and repairs in dry docks.

Event Structures

In non-construction scenarios, Cuplock scaffolding is also employed to create stages, temporary seating, and platforms for large-scale public events.

Cuplock Scaffolding Assembly and Safety Guidelines

Step-by-Step Setup

- Prepare and clear the job site, ensuring a level foundation.

- Position and level base plates or jacks.

- Insert vertical standards into base plates.

- Lock horizontal ledgers into the fixed cups and rotate top cups to secure them with a hammer tap.

- Continue to build upward and outward, adding braces and hop-up brackets as needed.

- Install toe boards, handrails, and any required safety netting.

Safety Best Practices

- Always inspect each component for damage or rust before use.

- Train workers on proper locking procedures and load limitations.

- Equip all personnel with PPE, including helmets and harnesses.

- Ensure scaffolds are never overloaded or modified without engineering approval.

Should You Rent or Buy?

Renting Cuplock is a good option for short-term projects or contractors who only need scaffolding occasionally. It reduces upfront costs and includes maintenance by the rental company.

Purchasing Cuplock is ideal for contractors managing multiple projects or long-term builds. While the upfront investment is higher, the ability to reuse components across jobs leads to significant savings over time.

Conclusion

Cuplock scaffolding is fast, safe, and scalable. Its unique locking mechanism eliminates the need for loose fittings and drastically speeds up construction. Whether you’re working on residential towers, bridges, factories, or event setups, Cuplock offers unmatched flexibility and performance.

Backed by industry certifications, supported by leading manufacturers, and trusted on job sites around the world, Cuplock scaffolding is the modern contractor’s choice for reliable, repeatable performance.

Frequently Asked Questions

What is the maximum load Cuplock can handle?

With correct spacing and configuration, Cuplock systems can support up to 74 kN on universal jacks—sufficient for heavy-duty tasks.

Can Cuplock be used for curved or circular structures?

Yes. Horizontals can be connected at multiple angles, enabling non-linear scaffold shapes like cylinders and ovals.

Is special training required to install Cuplock?

Yes. Installers should undergo certified training covering scaffold erection, load management, and safety inspections.

How long does Cuplock scaffolding last?

With proper maintenance and storage, hot-dip galvanized Cuplock components can last over 10 years, even under harsh site conditions.