- 388 Dongwu South Road, Suzhou City, P.R.China

- info@apacscaffold.com

- 0086-512-66700084

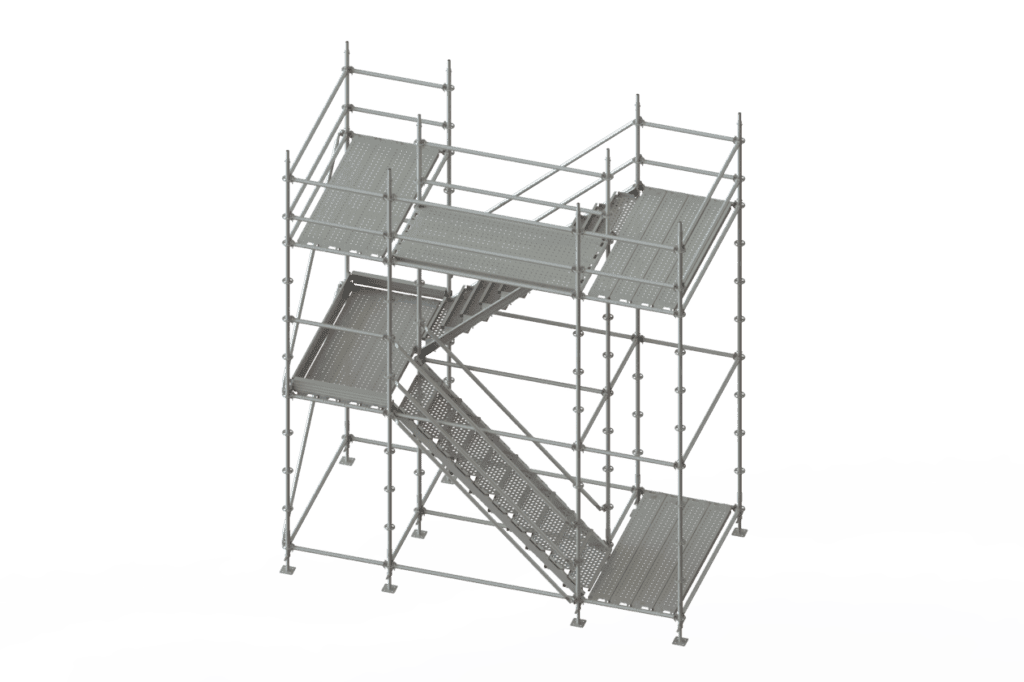

Aluminum ring scaffolding is an efficient, safe, and environmentally friendly scaffolding system made from high-strength aluminum alloy. It provides excellent stability and load-bearing capacity through its unique ring design and can meet the needs of workers of all weight classes.

Alu Alloy Grade: 6061-T6, 6082-T6

Aluminum Tube Dimension: O.D 48.4×4.2mm.

Surface Finishing: Self-finishing, Powder Coated

Alu Alloy Grade: 6061-T6, 6082-T6

Threaded rod diameter: 38mm

Finished: Hot dip galvanized

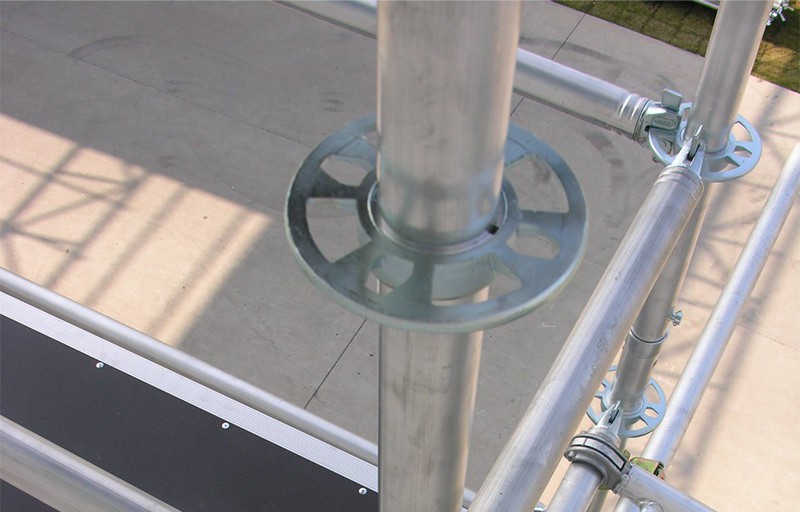

Material: Aluminum Alloy 6061-T6

Size: Standard Post Diameter Φ48.4mm

Scaffolding Height: without height restriction

Aluminum Tube Dimension: O.D 48.4×4.2mm.

Alu Alloy Grade: 6061-T6, 6082-T6

Ledger Connector: Casting aluminum

It allows access for a scaffolding project requiring unique and safe access to certain levels of your working platform.

Material: Alloy 6061 T6

Height: 1.0m, 2.0m

Length: available with your bay.

Aluminium scaffolding has good corrosion resistance. Aluminium scaffolding has a layer of oxide film on its surface, which can resist the erosion of air and water, so it has good corrosion resistance. Compared with traditional steel scaffolding, aluminium scaffolding is not easy to rust and has a longer service life. In addition, aluminium scaffolding has high strength and load-bearing capacity, which can meet various construction needs. The excellent corrosion resistance of our aluminium scaffolding is due to our strict selection of high-quality raw materials, precision machining and heat treatment to ensure the strength and corrosion resistance of the scaffolding.

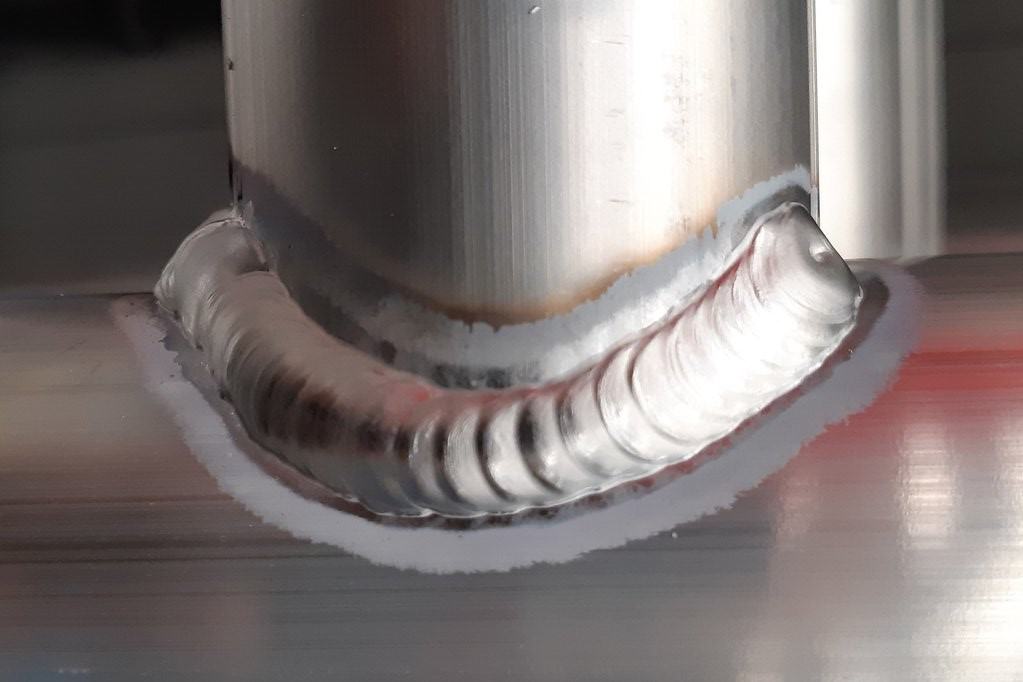

We use advanced welding technology to ensure that every weld meets perfect quality standards.

During the welding process, we use high-precision welding equipment to ensure accurate alignment and complete fusion of the welds. At the same time, we strictly control the welding parameters, including welding current, welding time, and welding speed, to obtain the best welding results. These measures ensure the strength and stability of the welds, enabling the aluminum scaffolding to maintain its structural integrity when subjected to loads.

Firstly, we attach importance to the packaging of our products. For aluminium scaffolding, we will customize suitable pallets according to the specific size and shape of the scaffolding, and fill the box with anti-vibration materials to reduce the impact of collision and vibration on the products that may occur during transportation.

Secondly, we pay attention to the transport of our products. When shipping aluminium scaffolding to its destination, we will choose an experienced and reputable logistics company to work with. We will communicate closely with the logistics company to ensure that the product receives proper attention and protection during transport.

Aluminum ringlock scaffolding has a wide range of application scenarios involving high-rise buildings, large industrial plants, complex bridge structures, and so on. It provides a safe and reliable working platform for aerial work, which guarantees the safety of workers and the smooth progress of work.

WhatsApp us