- 388 Dongwu South Road, Suzhou City, P.R.China

- info@apacscaffold.com

- 0086-512-66700084

Scaffolding debris nets are commonly utilized in the construction industry. They serve as temporary barriers around construction sites or can be placed on scaffolding to prevent debris from entering or falling off buildings. Moreover, they are frequently employed to catch falling debris during demolition projects. This versatile type of netting is an excellent choice for safeguarding pedestrians and traffic, and has gained widespread usage in the construction field.

Material: 100% virgin HDPE with UV

Shade rate: 30%-95%

Length: 6m, 15m

Width: 1.8m

Material: 100% virgin HDPE with UV

Weight: 60g/sqm–300g/sqm

Width: 1m-6m,as your request

Length: 50m-300m,etc.

Material: 100% virgin HDPE with UV

Size: 3*50M;or Customized

Weight: 100gsm;or Customized

Shade rate: 30-95%

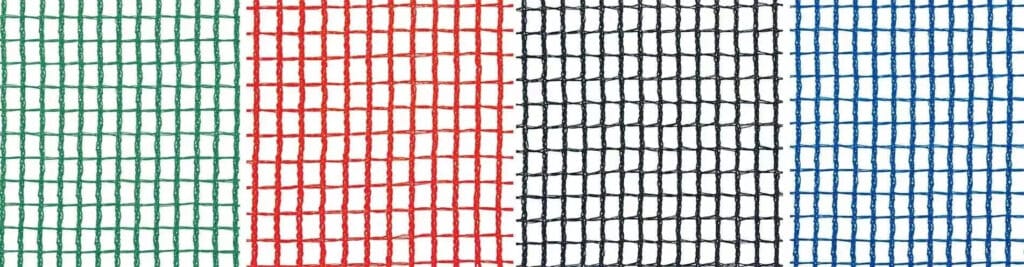

Material: 100% virgin HDPE with UV

Hole size: 1/4″ or 1/8″/1/16″

Size: 3*45m;or Customized

Weight: 90gsm;or Customized

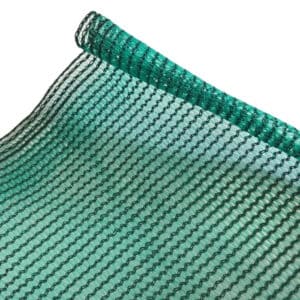

Material: 100% virgin HDPE with UV

Weight: 30gsm-300gsm

Type: Warp Knitted

Length: 5-100 m as your request

The primary advantage of using debris netting is enhanced safety. It creates a barrier between the construction area and the surrounding environment, preventing debris, tools, or materials from falling and potentially causing injuries to workers or bystanders below. It helps to create a safer work environment by reducing the risk of accidents and promoting a culture of safety on-site.

Debris netting acts as a containment system, capturing and containing loose debris, dust, or small particles generated during construction activities. This helps to maintain a clean and organized work area, preventing debris from spreading to adjacent properties, roads, or public spaces. It can also help to comply with environmental regulations by reducing the impact of construction activities on the surrounding area.

Debris netting can provide some degree of protection against weather elements, such as wind, rain, or snow. It acts as a windbreak, reducing wind velocity and minimizing the potential for wind-blown debris. It also helps to shield workers and construction materials from direct exposure to rain or snow, maintaining productivity and protecting sensitive equipment or materials.

In certain construction projects, such as renovations or sensitive installations, debris netting can provide privacy and security. It prevents unauthorized access to the construction site, discourages theft or vandalism, and shields the project from prying eyes.

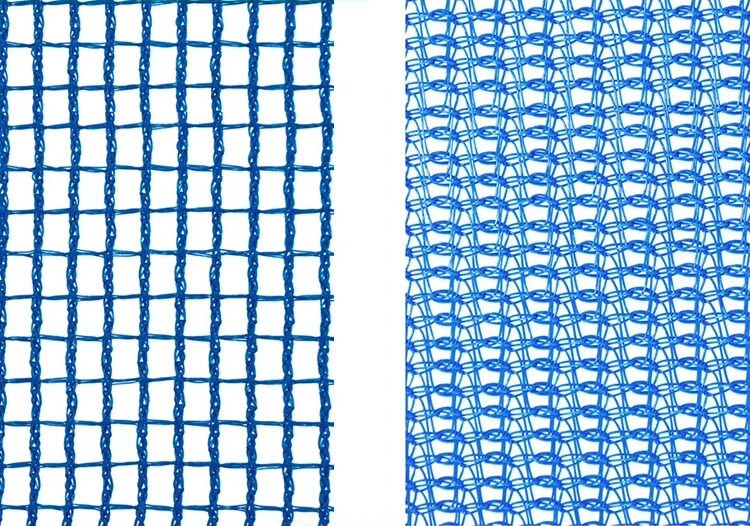

How to distinguish:If the threads appear to have loops, then it’s knit; if the threads have a perpendicular criss-cross pattern, it’s woven.

Main Difference:

There are two main types of scaffold netting, horizontal and vertical. As the names imply, the difference is how they are hung.

They can also serve to protect workers from falling from high distances, however it is important to not rely on these nets as the main source of fall protection, and instead to use proper fall protection procedures and use the horizontal netting as a backup.

USA = NFPA

UK = BS 4955

CAN = CAN/ULC-S101

AUS = AS1530

If you need scaffold debris netting in your projects, just reach out to a member of our team, we can make the debris netting according to your needs.

The following is some additional information about our debris netting. If you are unable to locate what you are searching for, please do not hesitate to contact us and we would be delighted to discuss the product with you.

Our edge protection systems have been tested intensively before being brought to market,we already have relevant test reports and videos.We provide samples, costs depend on the price of the products. Sample fee and freight cost shall be paid by the buyer.Please do not hesitate to contact us if you have any interest.

Upon your first formal order in considerable quantity, we will return it to you.

Available sample order, 3 - 7 days;mass production order, 10 - 40 days (based on different quantities);For some distant places, the delivery time may be a little bit longer.By Express: DHL UPS TNT FEDEX or EMS E-packing.By Sea: Inform us of the Sea Port to check which ship line.

It also depend on stock quantity, whether it's customized products etc.

Yes, we require all international orders to have a minimum order(MOQ) quantity.Orders less than MOQ are not cost effective due to the combined costs of shipping costs and duties. We recommend you to buy from our local distributor.

We provide B/L, commercial invoice, packing list, Certificates of Analysis / Conformance, Insurance, Origin, and other export documents where required. If you require further documentation, please advise.

WhatsApp us