Introduction

In high-stakes construction environments, every component matters. Ringlock system scaffolding has rapidly become a global favorite among contractors, engineers, and project managers — and for good reason. Its modular design, high load capacity, and intuitive assembly make it ideal for everything from residential projects to massive industrial jobs.

Whether you’re new to the system or looking to upgrade your scaffold fleet, here are 7 reasons why Ringlock scaffolding should be your go-to solution.

Outstanding Versatility and Design Flexibility

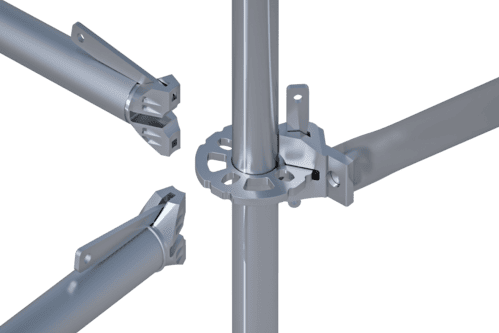

Ringlock scaffolding is engineered to adapt. Thanks to the innovative rosette connector, which provides up to 8 connection points at each node, you can build at multiple angles with precision. This allows scaffolders to:

Create curved, sloped, or multi-angle structures

Adapt easily to irregular facades or confined spaces

Customize setups for bridges, tunnels, shipbuilding, and offshore rigs

Its modular design enables almost unlimited configurations, allowing crews to solve complex access challenges with ease.

Want to compare different scaffolding types? Check out APAC Scaffold’s guide to types of scaffolding in construction.

Speedy Assembly and Disassembly

Time savings on-site translate to real cost savings. Ringlock’s intuitive connection system requires just a hammer to lock standards, ledgers, and braces into place:

No loose fittings or bolts

Minimal components to manage

Easy learning curve, even for less experienced workers

Faster scaffold erection and dismantling means more efficient scheduling and reduced labor costs.

Superior Load-Bearing Performance

Strength is non-negotiable in construction — and Ringlock scaffolding delivers. Made from hot-dip galvanized steel or high-tensile aluminum, the system is designed to support significant loads:

Up to 6 kN/m² (approx. 612 kg/m²) in supported applications

Suitable for shoring, material loading platforms, and formwork support

Withstands harsh weather and heavy-duty use

This makes Ringlock an ideal choice for infrastructure and industrial projects that demand strength and stability.

Easy to Store and Transport

Efficiency doesn’t stop when the scaffold comes down. Ringlock components are:

Lightweight and compact

Stackable due to the flat rosette design

Stable during transport (notches prevent rolling)

Less space in the warehouse and fewer trips to the job site equal lower overhead costs.

Long-Term Durability

Ringlock systems are built to last. With hot-dip galvanization and weather-resistant finishes:

Components resist rust, corrosion, and mechanical wear

Suitable for marine, coastal, or rainy environments

Lower maintenance costs and longer lifespan

Whether you’re using steel or aluminum variants, durability ensures you get maximum ROI over the system’s lifecycle.

Enhanced Safety and Fewer Errors

Ringlock scaffolding’s prefabricated connections and secure locking mechanism reduce the margin for error:

Stable joint connections ensure structural integrity

Non-slip surfaces and guardrails improve worker safety

Fewer tools and simplified assembly reduce risk of incorrect setups

These features help contractors meet international safety standards with confidence.

Compliance with International Safety Standards

Top-tier Ringlock scaffolding systems are designed to meet or exceed major international safety and quality standards. This ensures you’re not only investing in a reliable system but also one that’s recognized for safety compliance across global markets.

Systems from reputable manufacturers like APAC Scaffold adhere to standards such as EN 12810/12811, ANSI/SSFI, and OSHA.

Certified manufacturing ensures consistency, structural integrity, and long-term durability.

Using compliant scaffolding helps you meet tender requirements, pass inspections, and protect your crew.

By choosing a system that aligns with international benchmarks, you’re protecting your workforce and your project timeline — a win-win for contractors operating in high-risk, regulation-heavy environments.

Conclusion

Ringlock scaffolding is more than just a trend — it’s a proven solution trusted by construction professionals worldwide. With unmatched versatility, strength, speed, and safety, it’s designed to meet the demands of modern job sites while maximizing return on investment.

Whether you’re working on a residential facade, a high-rise tower, or an offshore platform, Ringlock scaffolding is built to help you work smarter, safer, and faster.

FAQ

What’s the difference between Ringlock and Cuplock scaffolding?

Ringlock uses a rosette connection allowing up to 8 connection angles; Cuplock uses a cup-and-lock design with fewer angle options. Ringlock is generally more flexible and better suited for complex projects.

Can I use Ringlock with other scaffold brands?

Yes, but always verify certifications and follow local safety regulations when combining components from different sources.

Is Ringlock scaffolding suitable for shoring?

Absolutely. Its high load-bearing capacity and modular design make it excellent for shoring applications.

Does Ringlock require special training?

No special training is needed, but following standard scaffold safety practices and assembly guidelines is essential for safe use.

How does Ringlock save money over time?

Faster installation, reusability, fewer errors, lower transport and storage costs, and compatibility with other systems all contribute to long-term cost savings.