Introduction

In the construction industry, scaffolding systems play a critical role in ensuring both safety and efficiency. Two of the most commonly used scaffolding systems are Cuplock and Ringlock. Both have been trusted globally for decades, yet they differ significantly in their design, flexibility, assembly, load-bearing capacity, and cost-effectiveness.

This comprehensive comparison will dive into the 10 key differences between Cuplock and Ringlock scaffolding. Whether you are managing a high-rise construction, industrial plant setup, or residential building project, understanding these differences is essential for making the right scaffolding choice. Read on to explore the technical nuances, performance advantages, and long-term benefits of each system to help you make an informed decision for your next project.

10 Key Differences Between Cuplock and Ringlock Scaffolding

1. Design Philosophy: Connection Mechanism and Structural Flexibility

Cuplock: Simplicity and Efficiency in Basic Scaffolding Configurations

Cuplock scaffolding is renowned for its simple yet robust design, focusing on ease of assembly and reliability. It features a cup-and-blade connection system, where each vertical standard has fixed metal cups at 500mm intervals. The horizontal ledgers have blades that fit into these cups, with the connection secured by rotating a top cup to lock the blades in place. This system supports up to four horizontal ledgers per node, and the typical configuration is 90° connections.

- Connection: Cuplock’s angular constraint makes it ideal for linear scaffolding applications, such as facade access, shoring, and standard vertical load-bearing tasks.

- Performance Implication: The rigidity of the Cuplock connection excels in providing outstanding strength under vertical loads, making it perfect for high-rise buildings and formwork systems. However, for complex or non-standard geometries, the design limits flexibility and requires additional components or adaptations.

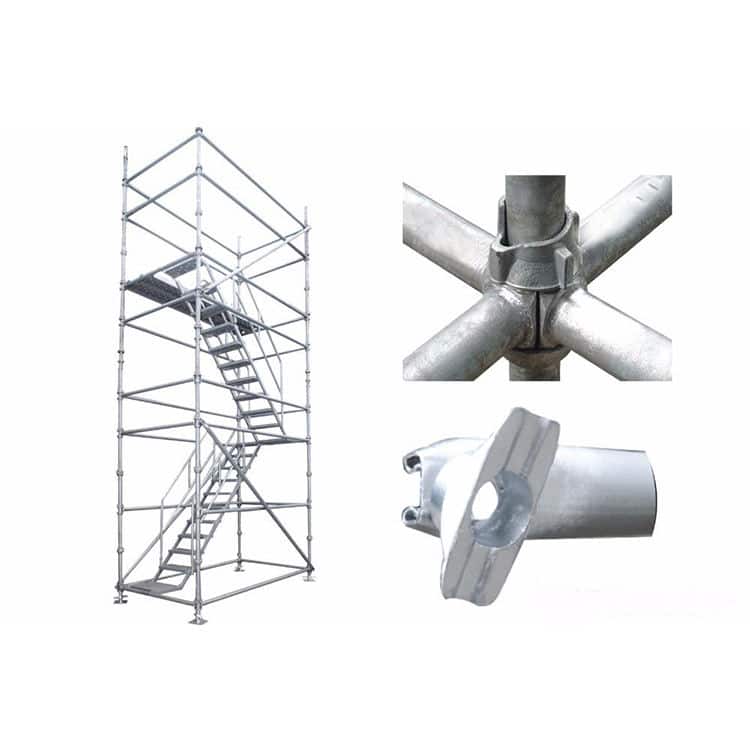

Ringlock: Multi-Directional Connectivity for Advanced Projects

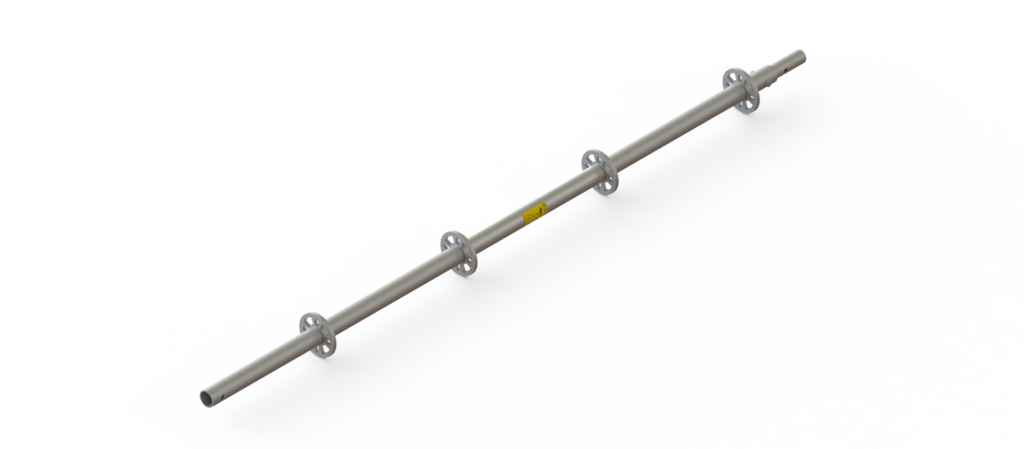

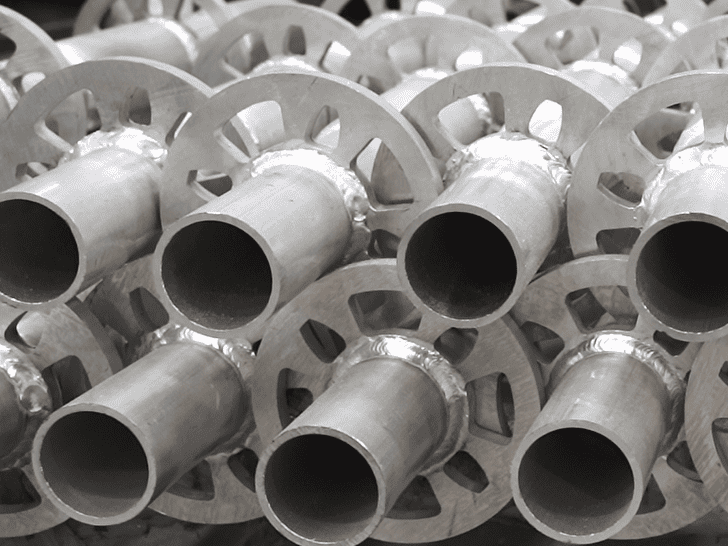

Ringlock scaffolding, designed for more complex scaffolding needs, integrates a rosette connection at each standard, which allows for eight attachment points — four smaller holes for vertical and horizontal connections, and four larger holes for angled bracing. The wedge connectors fit into these slots and are secured by hammering.

- Connection: This system’s ability to connect in multiple directions (45°, 90°, 135°) makes it more versatile and capable of handling complex structures such as curved facades, industrial plants, and non-linear designs.

- Performance Implication: The Ringlock system excels in projects requiring multi-plane bracing and lateral stability, providing superior structural integrity for complex geometries and dynamic load conditions. This makes it ideal for environments with variable loads, high wind forces, or irregular architectural designs.

2. Load-Bearing Capacity and Structural Integrity

Cuplock: High Vertical Load-Bearing, Ideal for Shoring Systems

Cuplock’s four-directional locking system provides strong vertical load-bearing capacity, making it particularly suitable for shoring applications. The system has been widely used in formwork support for concrete slab projects and heavy vertical loads.

- Vertical Load-Bearing Capacity: Cuplock is robust in handling static vertical loads, such as temporary structural support for slabs, beams, and formwork.

- Limitations: Cuplock’s limited connection flexibility under lateral forces (e.g., wind loads) means it may require additional bracing in environments with non-vertical forces or for high-rise buildings with irregular shapes.

Ringlock: Superior Load Distribution for Multi-Directional Forces

Ringlock provides superior load distribution across multiple directions. Its eight-way rosette connection and the ability to integrate diagonal bracing in any direction make it highly adaptable for complex, multi-dimensional scaffolding.

- Lateral Stability and Load Distribution: Ringlock excels at distributing forces evenly across the scaffolding structure, which enhances lateral stability under wind loads, dynamic forces, and rotational stresses.

- Performance in Complex Structures: For projects like high-rise buildings, bridges, and industrial plants, Ringlock offers higher load-bearing capacity and greater safety due to its ability to maintain structural integrity during complex and shifting conditions.

3. Assembly Speed and Labor Efficiency

Cuplock: Swift for Standard, Linear Structures

Cuplock’s cup-and-blade system enables rapid assembly, especially for repetitive and linear scaffolding layouts. The straightforward locking system requires less precision, which is ideal for standardized applications.

- Assembly: Cuplock’s simplicity leads to faster setup in straightforward scaffolding tasks like facade access and temporary shoring.

- Labor Efficiency: The ease of installation allows for quicker training and deployment of workers on standard construction sites, reducing on-site labor time for repetitive configurations.

Ringlock: Faster for Complex, Custom Configurations

Although Ringlock might take slightly longer to assemble initially due to the precision required in fitting the wedge connectors into the rosette slots, its design allows for fewer adjustments during complex setups. The eight-way connection also reduces the need for custom components.

- Assembly: Ringlock’s multi-directional flexibility significantly reduces adjustment time during the erection of complex scaffolds, such as multi-level or irregular-shaped projects.

- Labor Efficiency: The modular nature and precision engineering of Ringlock reduce specialized labor requirements and enhance overall site efficiency.

4. Cost and Long-Term Investment Considerations

Cuplock: Cost-Effective for Standard Builds

Cuplock’s simplicity and ease of use make it a more cost-effective solution upfront, particularly for standard configurations. For small to medium-sized projects where budget constraints are paramount, Cuplock remains the most economical option.

- Upfront Costs: Cuplock’s lower initial material cost makes it an attractive choice for standardized applications where minimal customization is required.

- Long-Term Value: The simplicity of Cuplock reduces the need for additional components, which helps lower operational costs for projects that require basic scaffold configurations and quick turnarounds.

Ringlock: Higher Initial Costs, Better ROI for Complex Projects

Ringlock, while having a higher initial cost, offers better ROI in the long term, especially in projects that demand frequent reconfigurations or complex scaffold designs.

- Upfront Costs: The advanced design and wider application range of Ringlock make it a more expensive initial investment.

- Long-Term Investment: Due to higher labor efficiency, reduced need for custom components, and greater durability, Ringlock is highly cost-effective for complex projects that require multi-level scaffolding or non-standard configurations.

5. Safety Aspects

Cuplock: Reliable but Manual Locking Risks

While Cuplock provides reliable stability, the manual rotation of the top cup can introduce safety risks if the components are not properly secured. Additionally, loose components can cause accidents if not checked regularly.

- Safety: Manual locking can lead to potential inconsistencies in securing the cups, introducing safety hazards in high-stress situations. Proper checks are necessary to ensure the system is properly assembled.

Ringlock: Enhanced Safety through Precision Locking

Ringlock’s wedge-locking mechanism ensures secure and rigid connections, making it safer during assembly. The automated wedge fitting provides better structural integrity and prevents human error.

- Safety: The precision fitting and secure wedge mechanism make Ringlock a safer option, especially for high-risk environments, as the connections are tightly secured with every installation.

6. Durability and Maintenance

Cuplock: Regular Maintenance Required

Cuplock is made from galvanized or painted steel and requires periodic maintenance to prevent rust and wear over time, especially in harsh environments.

- Maintenance: Regular inspection and maintenance are required to ensure the system’s longevity, particularly in regions with harsh climates or exposure to moisture.

Ringlock: Superior Durability with Hot-Dip Galvanization

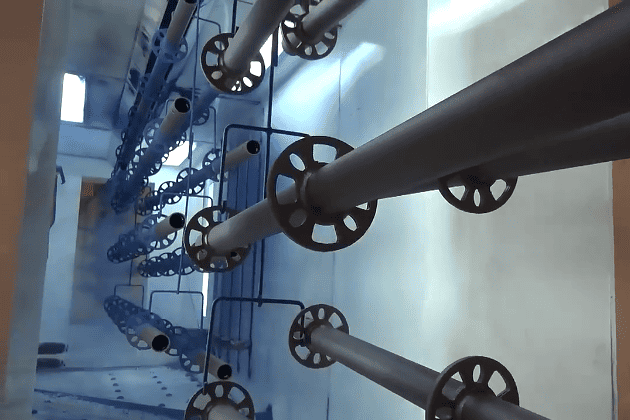

Ringlock components are typically hot-dip galvanized, providing superior corrosion resistance and requiring less frequent maintenance.

- Maintenance: The galvanized components of Ringlock ensure longer service life, reducing the need for frequent replacements and maintenance over time.

7. Storage and Transportation

Cuplock: Bulkier, Requires More Storage Space

Cuplock scaffolding requires more storage space due to its top and bottom cup components, making it more difficult to transport and store efficiently.

- Storage and Transport: The additional components increase logistical costs due to bulkier storage and higher transport volume.

Ringlock: Compact and Easier to Transport

With fewer components (primarily rosettes and ledgers), Ringlock is more compact, making it easier to store and transport efficiently.

- Storage and Transport: Ringlock’s compact design reduces the space required for storage and transportation, making it more cost-effective in logistics.

8. Labor and Training Requirements

Cuplock: Requires Basic Training in Locking Mechanism

Cuplock’s system, though simple, requires manual labor to lock and secure the components. It’s crucial for workers to be trained in the proper techniques to avoid misalignment.

- Training: Workers must be trained in cup-and-blade locking techniques to ensure the system is correctly assembled and secure.

Ringlock: Easier to Train Workers Due to Intuitive System

Ringlock’s wedge-locking mechanism and rossettes are more intuitive, which reduces skill dependency and training time for workers.

- Training: The rosette system is easy to learn, enabling faster training for new workers and reducing the learning curve compared to Cuplock.

9. Regulatory Compliance and Industry Standards

Cuplock: Widely Accepted with Limited Compliance in High-Risk Applications

Cuplock is widely accepted and compliant with industry standards in many countries. It is a proven system with a long track record of use in standard construction projects. However, in some high-risk environments or in projects that require strict safety regulations (such as bridge construction or industrial plants), Cuplock may need to undergo additional engineering checks or adaptations to ensure full compliance with higher standards.

- Regulatory Considerations: Cuplock is suitable for general construction but may face challenges in meeting the more stringent standards required for certain high-risk projects.

Ringlock: More Commonly Used in High-Safety Compliance Projects

Ringlock scaffolding is designed with higher safety compliance in mind, making it more suitable for high-risk applications such as bridge construction, tunnel work, and industrial facilities. The multi-directional connection design and higher load capacity of Ringlock scaffolding meet the rigorous safety and performance standards required for complex infrastructure projects, where compliance with international standards like EN 12810 and OSHA is critical.

- Regulatory Compliance: Ringlock is more commonly used in projects requiring advanced safety certifications and compliance with higher-risk industry standards, providing greater peace of mind for compliance officers and project managers.

10. Environmental Impact and Sustainability

Cuplock: Standard Environmental Impact

Cuplock scaffolding is a widely used, cost-effective solution, but due to its simpler design, the components are typically heavier, and the system requires more frequent maintenance to ensure longevity. This could result in more material use over time and a higher environmental footprint compared to more advanced systems. Additionally, frequent inspections and maintenance may increase the carbon footprint of projects due to transportation and disposal of worn components.

- Environmental Impact: Cuplock’s more frequent need for repairs and its bulkier components can contribute to higher environmental costs when scaling projects over time.

Ringlock: Advanced Design with Sustainability in Mind

Ringlock scaffolding’s efficient, modular design and compact storage can help reduce environmental impact over time. Its higher durability, longer lifespan, and reduced need for maintenance ensure that fewer materials are used in the long run, making it a more sustainable option. Furthermore, the modular nature of Ringlock allows for reuse and reconfiguration, reducing the need for manufacturing new components and minimizing waste.

- Environmental Impact: Due to its greater durability and reuse potential, Ringlock can be considered a more sustainable option for large, complex projects, contributing to lower long-term environmental impact.

Comparison Table: Cuplock vs. Ringlock Scaffolding

Feature | Cuplock Scaffolding | Ringlock Scaffolding |

Connection Mechanism | Cup-and-blade system (up to 4 connections) | Rosette-and-wedge system (up to 8 connections) |

Flexibility | Limited to 90° angles | Multi-directional (45°, 90°, 135°) |

Load-Bearing Capacity | High vertical load-bearing capacity | Superior load distribution (multi-directional) |

Assembly Speed | Faster for standard, linear layouts | Faster for complex setups (multi-level/curved) |

Cost | More affordable upfront | Higher initial cost, but better ROI over time |

Durability | Requires regular maintenance | Hot-dip galvanized for superior corrosion resistance |

Safety | Manual top cup can lead to safety risks | Enhanced safety with wedge-locking mechanism |

Storage and Transport | Bulkier, requires more space | Compact, easier to store and transport |

Labor Training | Requires more training for manual system | Easier to train workers due to intuitive system |

Regulatory Compliance | Accepted globally, but less suitable for high-risk projects | Preferred for high-risk and industrial projects |

Conclusion

Choosing the right scaffolding system — Cuplock or Ringlock — depends on your project’s complexity, time constraints, and structural requirements. Cuplock is an excellent choice for standardized, high-load-bearing applications where cost-effectiveness and speed are paramount. It is a reliable option for routine projects such as facade access, shoring, and formwork support.

On the other hand, Ringlock is ideal for complex, large-scale projects requiring multi-directional flexibility, high load-bearing capacity, and faster assembly for intricate configurations. Its higher initial cost is often justified by the long-term savings in labor and its ability to handle dynamic loads, making it the preferred option for high-rise buildings, infrastructure, and industrial projects.

Contractors and project managers should evaluate the specific demands of their projects — whether flexibility, speed, cost, or structural integrity — to choose the most suitable scaffolding system for safe and efficient construction.

FAQ

Which scaffolding system offers the best long-term value?

While Cuplock has a lower initial cost, Ringlock offers better ROI over time, especially for complex projects due to its durability, versatility, and reduced labor costs.

What system is better for high-risk, high-demand projects?

Ringlock provides enhanced safety, corrosion resistance, and load distribution, making it ideal for high-risk environments, such as bridges and industrial plants.

Which system is more cost-effective for small projects?

Cuplock is more cost-effective for small-scale, standard scaffolding needs where design simplicity and low material costs are the priority.

Which system is easier to assemble and disassemble?

Ringlock offers faster assembly and greater flexibility, particularly for complex, multi-level scaffolds, while Cuplock may take longer for intricate designs due to its manual locking system.

Can I mix Ringlock and Cuplock components on the same scaffold?

No. The locking mechanisms (rosette vs. cup) are fundamentally different and incompatible. Attempting to mix components from different systems compromises the structural integrity of the scaffold and violates safety standards like EN 12811 and OSHA regulations.

Is Ringlock always more expensive than Cuplock?

In terms of initial purchase price, Ringlock is typically 15-20% more expensive due to higher steel grades and the galvanization process. However, Ringlock often proves cheaper in the long run (Total Cost of Ownership) because it lasts longer, requires less maintenance, and saves labor time on complex projects.

Which system is better for high-rise construction?

Ringlock is the superior choice for high-rise projects. Its high-strength low-alloy steel (Q355) and secure multi-directional connections provide the necessary load-bearing capacity and stability required for tall structures, which Cuplock may struggle to support efficiently.