- 388 Dongwu South Road, Suzhou City, P.R.China

- info@apacscaffold.com

- 0086-512-66700084

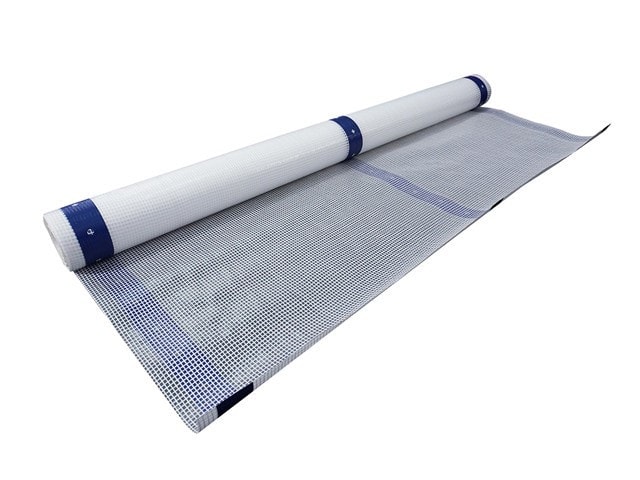

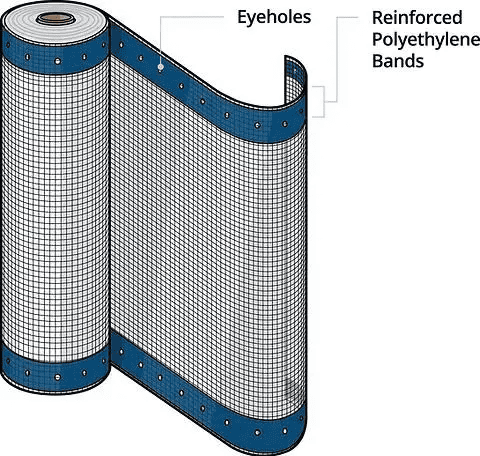

The scaffold sheeting is made of laminated polypropylene with reinforced webbing with pre-punched eyelets.

It acts as a shield to ensure a stable working climate on the scaffold, protecting your personnel from rain, sleet, and wind chill.

Reinforced band: white, blue, green

Special Treatment: UV/FR(Fire Retardant)

Package: Roll-up Tarp, Bale packing

Logos or other company information could be printed on tarpaulin.

Reinforced strip(7.5cm) could be added.

We have advanced production lines for export business, and each step is carefully crafted to ensure that the quality and performance of our products meet the highest standards. First, we use advanced weaving technology to weave high-quality HDPE material into a strong and durable mesh structure, providing a solid foundation for subsequent processing.

Next, after a precise cutting process, we cut the material into the desired shapes and sizes, striving to make each piece fit the design. To give the product a unique character, we introduce advanced printing technology to print beautiful patterns and text on the surface, making each piece one-of-a-kind. The sewing process, on the other hand, pays attention to details and firmly sews the parts together to ensure the durability and stability of the products.

Our scaffolding boards are designed to be very practical. The reinforcement tape on both sides can be made into 7cm or 14cm, which can be chosen according to the actual needs, enhancing the resistance strength of the scaffolding boards. Meanwhile, the length of a roll is basically 2m × 45m or 3m × 45m.

In addition, our scaffolding boards have excellent ventilation and air permeability and UV resistance, which can adapt to outdoor use for a long time. This kind of not only improves the safety of construction, but also reduces the frequency of maintenance and replacement, which saves the cost for customers.

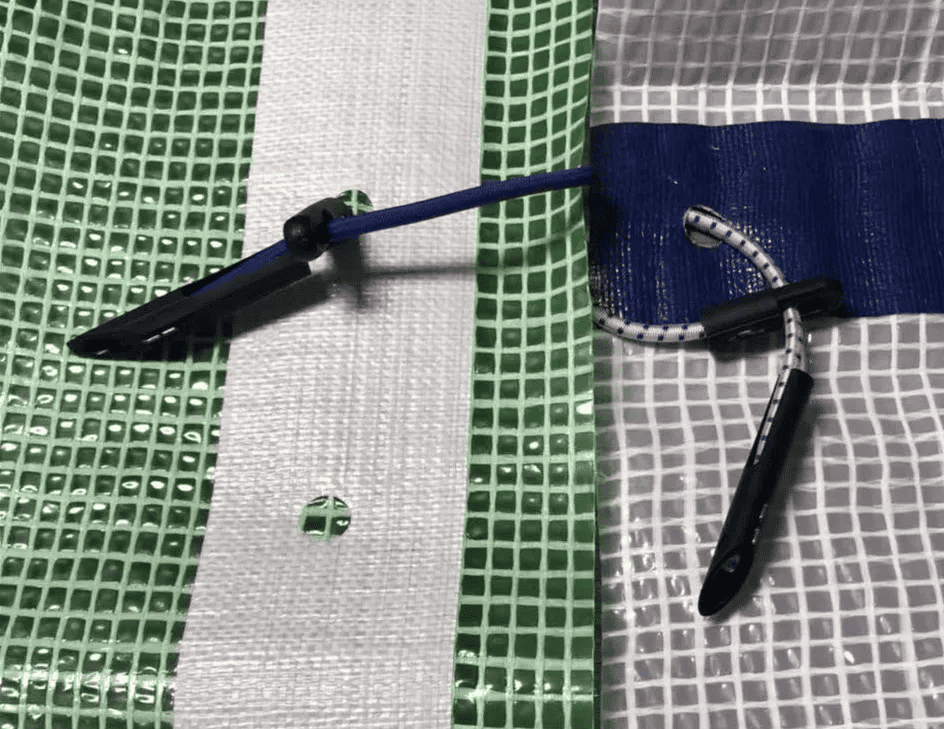

The scaffold sheeting is secured to the scaffolding by elasticated ties with pre-set eyelets on the eyelet tape at 4″ intervals for easy fixing and adjustment. This design allows the scaffold sheeting to fit snugly on the scaffolding, improving overall structural stability and safety. The use of elasticated ties also makes the installation and removal process easier and quicker, reducing construction time and costs. The pre-set eyelets can be adjusted according to the actual needs, adapting to different construction environments and requirements.

In the packaging segment, we provide a variety of packaging methods for you to choose from. Specifically include:

In addition, for customers with special packaging needs, we can also provide customised packaging solutions.

WhatsApp us