- 388 Dongwu South Road, Suzhou City, P.R.China

- info@apacscaffold.com

- 0086-512-66700084

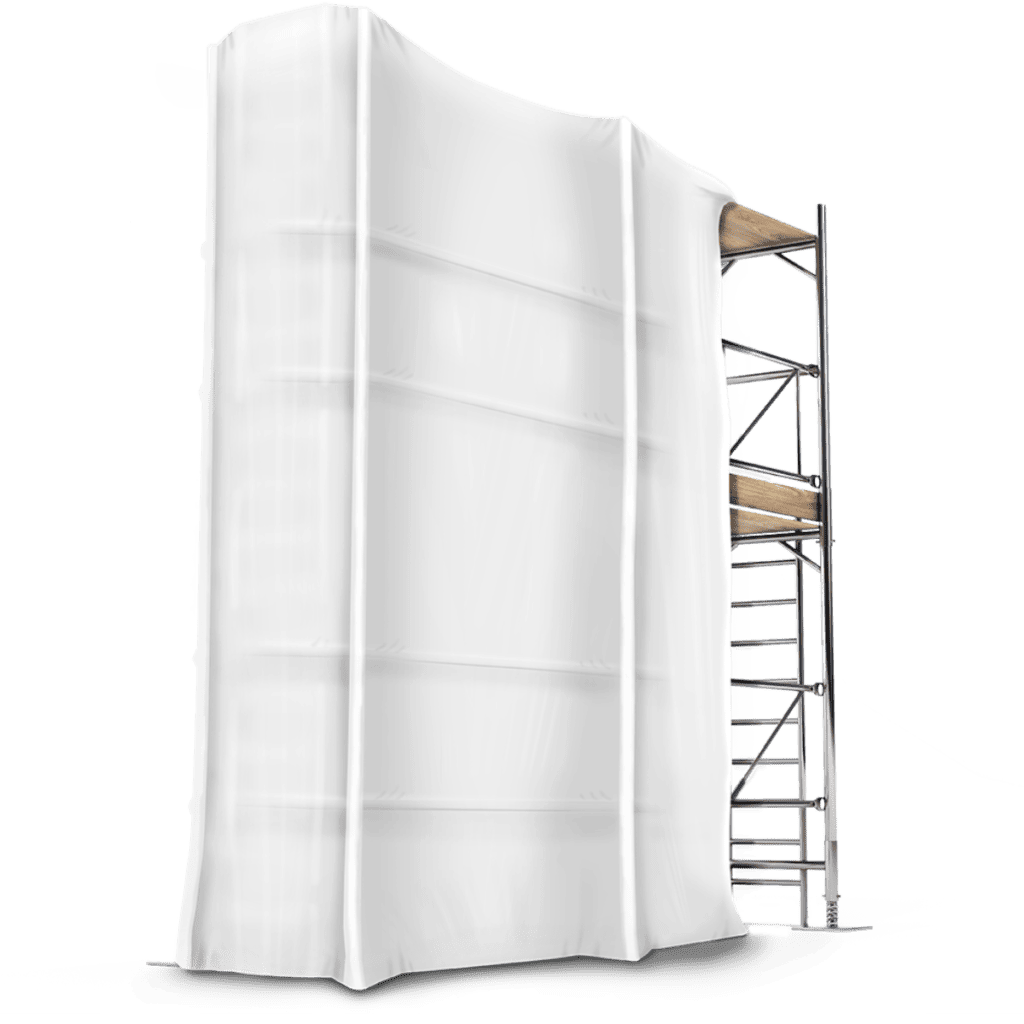

Scaffold shrink wrap is a protective covering used to enclose scaffolding structures. It is typically made of polyethylene material and is applied using heat to create a tight, weatherproof seal around the scaffolding.

With added strength, tear resistance and thickness, reinforced shrink wrap is ideal for more rugged environments or when additional durability is required.

Standard shrink wrap is designed to provide weatherproofing, containment, and durability, making it suitable for many construction and maintenance projects.

Fire retardant shrink wrap is designed to meet fire safety regulations, this type of shrink wrap is often used in construction projects where fire resistance is a consideration.

Scaffold shrink wrap helps to protect the structure and workers from wind, rain, and snow, while also providing containment for any debris or materials used during construction or maintenance projects, so we should give priority to durability.

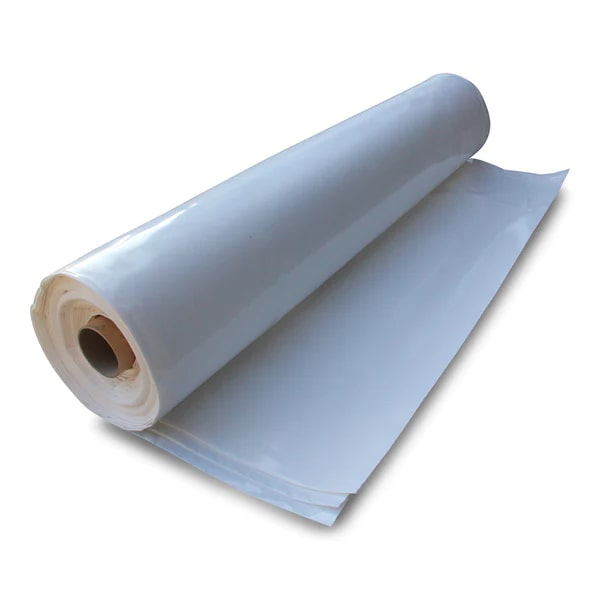

When packaging shrink wrap, APAC considers several key factors including ease of operation, protective effectiveness, and convenience of storage and transportation.

Initially, we well bind the shrink wrap into a roll to ensure its neatness. This approach not only preserves the integrity of the material, but also minimizes creasing during storage and transportation. Furthermore, in order to enhance protective measures and prevent dust and dirt accumulation, we encase the roll of shrink wrap in a durable plastic bag. This additional layer of protection ensures that the scaffold shrink wrap remains in its original state in any environment until its next use. Moreover,this packaging method offers exceptional convenience for both storage and transportation. Its compact roll design enables placement in various storage spaces and reduces the risk of damage during transit.

Customers can obtain all our scaffold shrink wrap needs, including product selection, customization, and delivery, from a single source, streamlining the procurement process.

As a manufacturer, we strictly check every stage from raw material selection to production processes, so as to ensure that each product consistently meets the highest quality standards. Moreover, We offer customized solutions, including specific sizes, packaging options, and material specifications, to meet the unique requirements of each customer and project. Furthermore, Our knowledgeable team can provide expert advice and support throughout the entire process, offering valuable insights and recommendations, so as to ensure our customers get the most satisfactory products.

WhatsApp us