- 388 Dongwu South Road, Suzhou City, P.R.China

- info@apacscaffold.com

- 0086-512-66700084

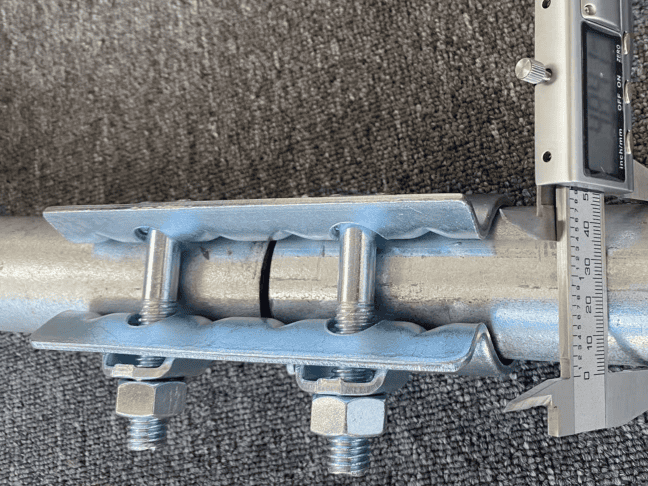

The Pressed Scaffold Sleeve Coupler—also known as a joint box or external coupler—is a critical component in modular scaffolding systems. It is engineered to join scaffold tubes end-to-end, creating a seamless extension with superior load resistance and anti-slip performance.

Manufactured from 4mm thick, high-tensile steel plates, each coupler is hot-dip galvanized (HDG) or electro-galvanized (zinc-plated) for corrosion resistance. The robust fabrication ensures consistent performance under heavy loading, while compliance with EN74 and BS1139 standards makes it suitable for use in global projects with stringent safety requirements.

Each coupler complies with EN74 Class B—an internationally recognized benchmark for scaffolding safety. This classification guarantees high mechanical strength and quality standards, including a tested slip resistance of over 9kN. Such performance is critical in load-bearing verticals and ledgers, ensuring the scaffold remains locked and stable under dynamic load shifts caused by wind, personnel movement, and material handling.

The coupler is available with two premium anti-corrosion finishes:

Zinc-Plated (E-gal): Electro-galvanized for a smooth, bright appearance, ideal for general construction environments with moderate weather exposure.

Hot Dip Galvanized (HDG): Coated with a thick zinc layer, HDG couplers provide superior protection against moisture, salt, and chemicals. This makes them especially suitable for marine construction, offshore platforms, and oil & gas sites where environmental corrosion is a primary concern.

These finishes significantly extend the product’s service life, reducing the frequency of replacements and delivering long-term value to contractors and distributors.

With no welding, threading, or special tools required, scaffolders can quickly connect two tubes by slipping them into the coupler and tightening the bolts. This results in:

The coupler’s user-friendly design is ideal for tight schedules and high-efficiency worksites, helping contractors meet project timelines without compromising safety.

To support supply chain visibility and professional branding, the sleeve coupler can be OEM marked with your company’s logo or code. This feature is ideal for:

OEM markings not only strengthen your brand identity but also support inventory tracking and traceability, which is essential for large-scale operations and compliance in many international markets.

WhatsApp us