Note: The scaffolding described in this article is a concept in the field of construction, not scaffolding in education, so if you are interested in learning about scaffolding in education, please read that article: https://www.buffalo.edu/catt/teach/develop/build/scaffolding.html

What is Scaffolding?

Scaffolding is an indispensable temporary structure in construction projects, specifically designed to meet the demands of working at heights and handling complex construction tasks. Different types of scaffolding are composed of various components, typically including vertical standards, horizontal ledgers, scaffold planks, and connectors. These are assembled at the construction site to provide a stable and safe working platform for construction workers. Scaffolding facilitates operations at heights and the installation of safety nets, ensuring that workers can perform their tasks safely and efficiently.

In this guide, we’ll walk through the history and uses of scaffolding, break down modern systems, compare materials, address common safety hazards.

The history of scaffolding

The history of scaffolding dates back thousands of years, and throughout human civilization, scaffolding has been an essential tool for construction and building maintenance. In ancient times, the Egyptians and Romans used simple wooden structures to help them construct large buildings. Similarly, ancient China utilized bamboo scaffolding structures. Although the tools they used may not be directly defined as scaffolding, we can consider them early prototypes of scaffolding.

By the Middle Ages, wooden scaffolding was used to construct churches and castles. Compared to ancient times, these structures had more recognizable features of modern scaffolding. Even today, in some remote or underdeveloped areas, you can still see this type of scaffolding in use.

In the modern era, scaffolding has become a highly regulated industry, with a focus on safety, efficiency, and sustainability. Modern scaffolding systems are usually made of steel or aluminum and feature modular designs that allow for quick assembly and disassembly. There are now comprehensive regulations for the installation, storage, and maintenance of scaffolding. After completing training courses, people can assemble scaffolding as easily as building blocks, making the process simple and fast.

What are the different types of scaffolding?

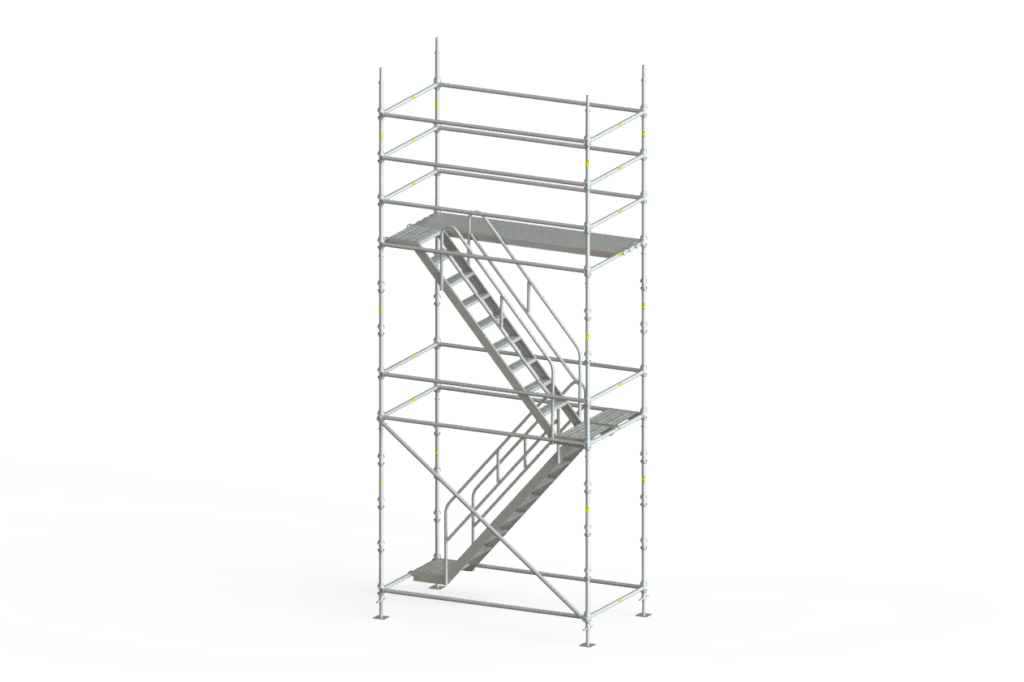

Modular Scaffolding

Modular scaffolding is a scaffolding system consisting of prefabricated components or modules that can be easily assembled and disassembled to form various scaffolding configurations. This type of scaffolding is versatile and adaptable for a variety of construction and maintenance projects.

Some of the more common ones are listed below:

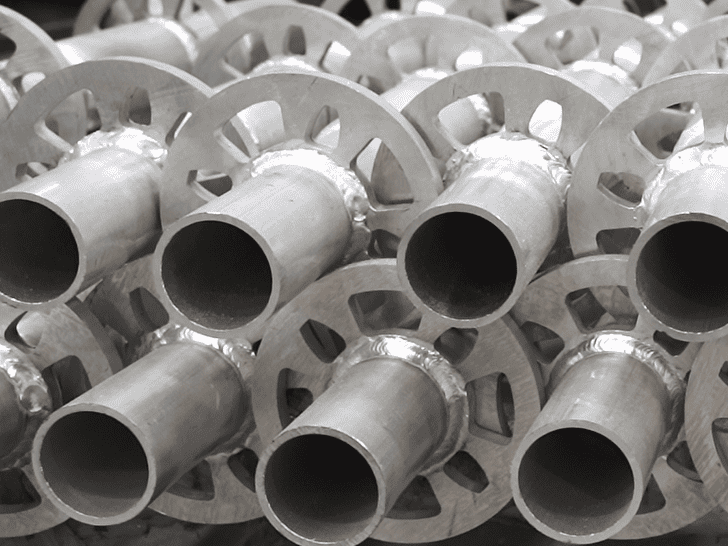

Ringlock Scaffolding

Overview: Ring lock scaffolding is a flexible and robust system that uses a rosette (a ring) as the central connector for vertical and horizontal components.

Key Features:

360-Degree Connections: The rosette allows for connections at multiple angles, offering flexibility in scaffold design.

Ease of Use: The components lock together easily with wedge or bolt systems, ensuring a secure structure.

High Durability: Often made of galvanized steel, ring lock scaffolding is highly resistant to corrosion and wear.

Common Uses: Complex structures, facade work, and industrial maintenance.

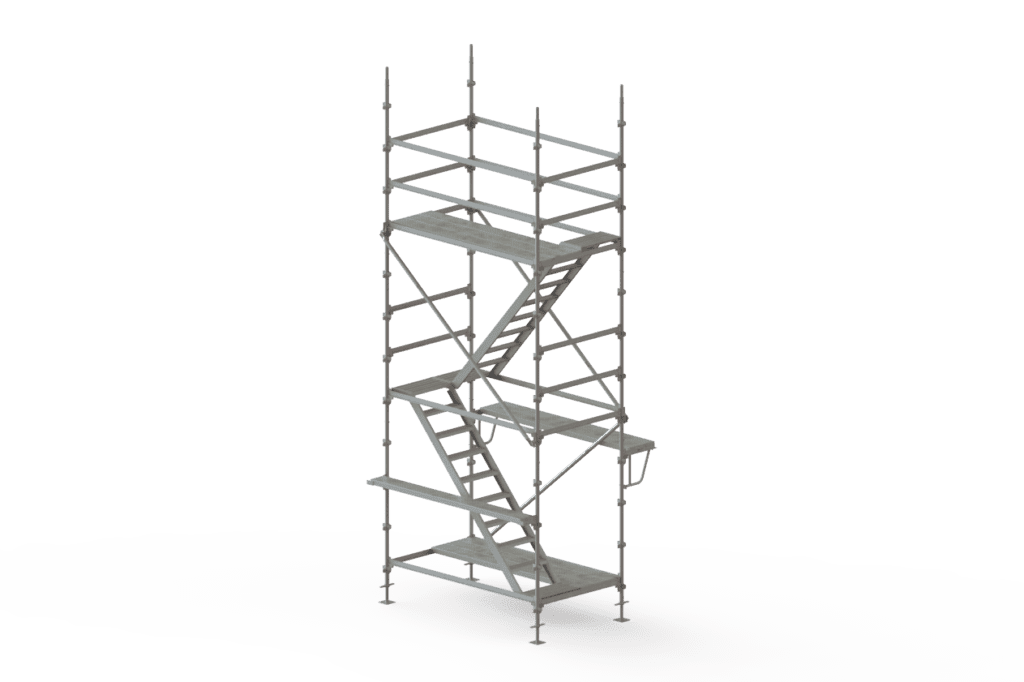

Cuplock Scaffolding

Overview: Cup lock scaffolding is a versatile system known for its unique locking mechanism, where a “cup” is used to lock horizontal components (ledgers) to vertical components (standards).

Key Features:

Quick Assembly: The cup mechanism allows for quick and secure assembly without the need for bolts or nuts.

High Load Capacity: Cup lock systems can support heavy loads, making them suitable for large-scale construction projects.

Common Uses: High-rise buildings, bridges, tunnels, and industrial projects.

Kwikstage Scaffolding

Overview: Kwikstage scaffolding is a modular system that features wedge connections, making it easy to erect and dismantle.

Key Features:

Versatility: Can be used for a variety of applications, from simple to complex structures.

Stable Platform: The wedge locking system ensures a stable and secure working platform.

Durability: Typically made of steel, Kwikstage scaffolding is strong and long-lasting.

Common Uses: Residential construction, commercial buildings, and refurbishment projects.

Tube & Clamp Scaffolding

Tube and fitting scaffolding, usually referred to as coupler scaffolding, is a system of scaffolding and support frames erected for building construction and subject to loads. This type of scaffolding consists of steel tubes and couplers, which are the connections between the tubes and are fastened by bolts. This type of scaffolding is more traditional than modular scaffolding.

Although not a “system” scaffolding in the modular sense, tube and fitting scaffolding is a highly adaptable form of scaffolding that uses standard tubes, fittings, and clamps to create a customized scaffold structure.

Key Features:

- Flexibility: It can be adapted to almost any shape or structure, making it ideal for complex or irregular projects.

- Customizable: Allows for precise adjustments to fit specific project requirements.

Common Uses: Restoration work, irregularly shaped buildings, and situations where standard modular scaffolding doesn’t fit.

Aluminum Scaffolding

Aluminum scaffolding is a type of scaffolding made from lightweight aluminum alloy, known for its ease of transport, assembly, and versatility. It is widely used in various construction, maintenance, and industrial applications due to its lightweight properties and corrosion resistance.

Key Features

Lightweight: Aluminum scaffolding is significantly lighter than steel, making it easier to transport, handle, and assemble.

Corrosion-Resistant: Aluminum is naturally resistant to rust and corrosion, making this type of scaffolding ideal for use in humid or corrosive environments.

Easy to Assemble: The lightweight nature and modular design of aluminum scaffolding allow for quick and easy assembly and disassembly without requiring heavy tools.

Durability: Despite being lightweight, aluminum scaffolding is strong and durable, capable of supporting significant loads.

Versatile: It can be used for a wide range of applications, from small-scale indoor projects to larger outdoor construction tasks.

Common Uses

Interior Maintenance and Painting: Ideal for indoor tasks like painting, electrical work, and light maintenance.

Construction: Used for lighter construction tasks where quick setup and mobility are essential.

Event Staging: Often used to build temporary structures like stages or platforms at events.

Industrial Maintenance: Particularly in environments where corrosion resistance is critical.

Mobile Scaffolding

Mobile scaffolding is a type of scaffolding mounted on wheels or casters, designed to be easily moved from one location to another without being dismantled. This mobility makes it ideal for tasks that require frequent relocation or covering large areas.

Key Features

Wheeled Base: Equipped with wheels or casters that can be locked into place for stability when stationary and unlocked for movement.

Lightweight and Portable: Often made from materials like aluminum to keep the structure light and easy to move.

Quick Setup and Mobility: Mobile scaffolding is designed for quick assembly and easy movement, making it highly efficient for tasks that require access to different parts of a structure.

Adjustable Height: Many mobile scaffolding systems allow for height adjustments, providing flexibility in different working environments.

Common Uses

Interior Work: Painting, plastering, electrical installations, and maintenance tasks where frequent repositioning is required.

Outdoor Maintenance: Cleaning windows, installing signage, or repairing facades where the scaffold needs to be moved along a building.

Event Setup: Setting up lighting, sound systems, or decorations where mobility is key.

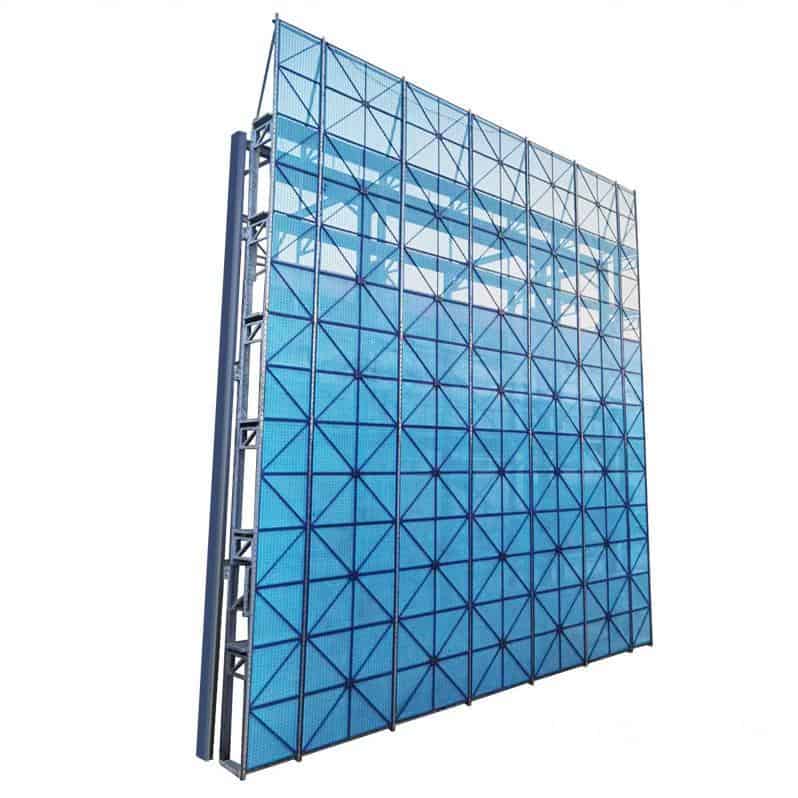

Climbing Scaffolding

Climbing scaffolding, also known as self-climbing or automatic climbing scaffolding, is an advanced type of scaffolding that can be raised or lowered automatically or semi-automatically as the construction progresses. This system is commonly used in the construction of high-rise buildings and tall structures.

What are the Basic Parts of Scaffolding?

Scaffolding is made up of several key components that work together to create a stable and safe structure for workers to perform tasks at height. Here are the basic parts of scaffolding:

1. Standards

Description: Vertical tubes that transfer the weight of the scaffold and the load it bears down to the ground.

Function: They serve as the primary support for the entire scaffolding structure.

2. Ledgers

Description: Horizontal tubes that connect the standards.

Function: They provide lateral support and help maintain the structure’s rigidity and stability.

3. Transoms

Description: Horizontal tubes placed at right angles to the ledgers, usually supporting the scaffold platforms.

Function: They provide additional support to the working platforms and help distribute the load across the structure.

4. Base Plates

Description: Flat plates are placed at the bottom of the standards.

Function: They distribute the load from the standards onto the ground and help prevent the scaffold from sinking into the ground.

5. Braces (Diagonal Braces)

Description: Diagonal tubes that connect standards and ledgers.

Function: They provide additional stability and prevent the scaffold from swaying or collapsing.

6. Scaffold Planks/Decks

Description: Horizontal platforms made from wood, metal, or other materials.

Function: They provide a working surface for workers to stand on while performing tasks.

What is the Best Material For Scaffolding?

Steel: Steel is the most commonly used material for scaffolding because it is strong, durable, and long-lasting. Q235 or Q355 grade steel is the most common.

Aluminum: Aluminium is another commonly used material for scaffolding because it is lightweight and easy to handle. It is also rust and corrosion-resistant, making it ideal for outdoor projects.

Wood and Bamboo: Wood and bamboo scaffolding are still used today, although not as commonly as steel or aluminum scaffolding. This material is usually cheaper and easier to work with than other materials. It is more prone to problems with transport and storage.

Fibreglass: Fibreglass scaffolding has become increasingly popular in recent years due to its lightweight, corrosion-resistant, and non-conductive properties. This makes it ideal for projects involving electricity. Overall though fibreglass scaffolding is a niche type of scaffolding.

Conclusion

Scaffolding remains an indispensable part of construction and maintenance projects. By understanding the different systems, components, materials, and safety best practices, companies can make informed decisions to ensure both efficiency and worker safety.

FAQ

What’s the strongest scaffold material for industrial use?

A: Steel (especially Q235 or Q355 grade) is the strongest and most suitable for heavy loads and long-term outdoor use.

Is aluminum scaffolding safe for outdoor use?

Yes, aluminum is corrosion-resistant and lightweight, though not suitable for very heavy-duty applications.

When should I choose tube & clamp over modular systems?

Tube & clamp is best for irregular structures or restoration projects that require customization.