Introduction

H Frame scaffolding is one of the most widely used temporary structures in the construction industry. Renowned for its strength, simplicity, and flexibility, this scaffolding system provides safe working platforms at elevated heights. Whether used for building construction, maintenance, painting, or industrial applications, H-frame scaffolding ensures stability and efficiency. In this guide, we break down the components, advantages, types, and best practices for using H-frame scaffolding in diverse construction environments.

Understanding H-Frame Scaffolding

Definition and Core Structure

H Frame scaffolding is characterized by its distinctive “H”-shaped vertical frames connected by horizontal and diagonal braces. These frames provide the primary load-bearing support, and when assembled, they form a robust and safe platform for workers and materials. Typically made from steel or aluminum, these systems are engineered to handle significant loads and harsh working conditions.

Where It’s Used

The versatility of H Frame scaffolding makes it suitable for:

Residential and commercial building projects

Industrial facility maintenance

Infrastructure construction (bridges, tunnels, viaducts)

Shipbuilding and offshore operations

Event staging and temporary structures

Restoration of historical buildings

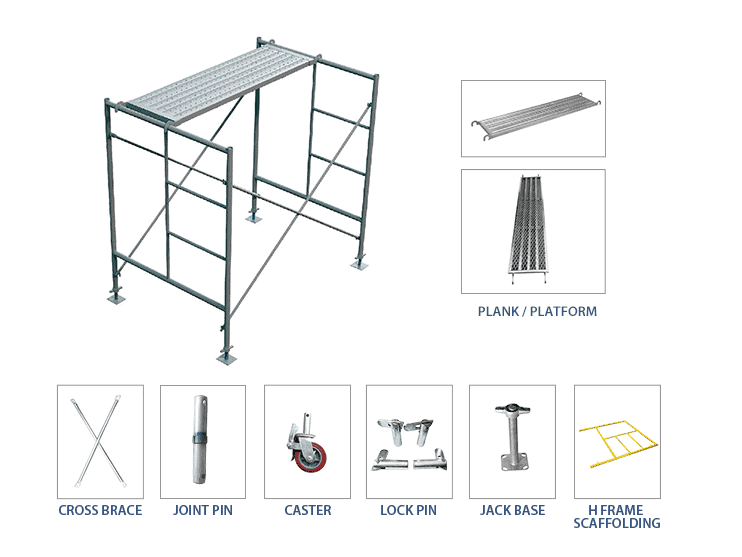

Key Components of H Frame Scaffolding

Structural Elements

H-Frames (Vertical Frames): These form the upright supports and come in varying heights.

Cross Braces & Ledgers: Diagonal and horizontal tubes that stabilize the structure and connect frames.

Scaffold Boards/Platforms: The working surface where personnel and tools are positioned.

Base Plates & Adjustable Jacks: Provide balance and allow the system to adapt to uneven ground.

Safety and Access Accessories

Guardrails & Toe Boards: Prevent falls and material drops.

Access Ladders or Ladder Frames: Built-in or add-on ladders ensure safe vertical movement.

Joint Pins & U-Head Jacks: Facilitate height customization and secure frame connections.

Advantages of H Frame Scaffolding

Ease of Assembly: Frames and braces are designed for quick locking, reducing setup time.

High Stability: The rigid structure minimizes swaying, even under dynamic loads.

Load Capacity: Platforms support up to 300 kg/m², suitable for heavy-duty use.

Adaptability: Can be configured to suit various heights, surfaces, and project demands.

Cost-Effective: Reusable materials and minimal tools reduce long-term project costs.

Safety: Complies with international standards (e.g., TS EN 12811-2, EN ISO 3834-3).

Types of H-Frame Scaffolding

Walk-Through Frames

Walk-through frames are engineered with a large open span between vertical posts, allowing workers to move freely through the scaffolding without ducking or navigating around horizontal bars. This design streamlines the workflow for façade work and continuous movement along building exteriors. It’s particularly useful in tasks such as plastering, painting, and cladding, where mobility is crucial.

Snap-On Frames

Snap-on frames utilize specialized snap-lock or pin-and-clip mechanisms that enable quick connection and disconnection of horizontal and vertical members. These frames are ideal for projects that require frequent relocation or reconfiguration of scaffolding. Their tool-free setup enhances speed and efficiency, especially on short-term or fast-paced job sites.

Mason Frames

Mason frames are optimized for masonry work, featuring fewer horizontal cross members at the working level to reduce interference. This gives masons unobstructed access to brick, block, or stonework, improving productivity and ergonomics. These frames also support heavy materials typically used in masonry tasks.

Single-Width and Double-Width Frames

Single-width frames are compact and best suited for narrow spaces or indoor applications. Double-width frames offer a wider working platform that accommodates multiple workers, materials, and tools, enhancing productivity on large-scale or exterior projects. The choice between the two depends on access space and the number of personnel working simultaneously.

Ladder Frames

Ladder frames include integrated vertical rungs or steps built into the frame structure, eliminating the need for separate ladders. This built-in access system ensures safety and efficiency when moving between scaffold levels. Ladder frames are ideal for multi-story projects or when frequent vertical movement is required.

Assembling and Using H Frame Scaffolding Safely

Step-by-Step Assembly Guide

Site Preparation: Begin by surveying the worksite to identify potential hazards or obstructions. Use a leveling tool to confirm even ground conditions and install base plates or adjustable jacks to accommodate minor slope variations. Ensure drainage or moisture issues are addressed to maintain a solid foundation.

Frame Positioning: Stand the H-frames upright at intervals corresponding to the scaffold’s intended width and height. Use a spirit level or plumb line to check vertical alignment. Secure frames in place with base jacks or fixed anchor points to prevent shifting during use.

Bracing: Connect diagonal cross braces between vertical H-frames to create X-shaped stabilizers. Begin at the base and work upwards, locking braces into designated slots or couplers. Install horizontal ledgers across each bay to reinforce the structure and prepare mounting points for platforms.

Platform Placement: Lay scaffold planks or metal decks across the ledgers, ensuring even distribution and secure fit. Confirm that each platform is free from damage, properly supported, and fastened if needed. Incorporate toe boards at platform edges to prevent tool or material slippage.

Safety Additions: Mount guardrails at all exposed edges to prevent falls. Install internal ladders or use ladder frames to allow safe ascent and descent between levels. Check all connections for tightness and compliance with site safety protocols before authorizing scaffold use.

Safety Precautions

Always wear Personal Protective Equipment (PPE): This includes hard hats, safety harnesses, gloves, high-visibility vests, and non-slip safety boots. Fall arrest systems should be used where required.

Respect Load Limits: Never overload platforms with excessive weight. Consider both personnel and materials when calculating total load. Use reinforced platforms for heavy-duty tasks.

Conduct Daily Inspections: Check for loose fittings, damaged frames, or worn platforms each day before use. Inspections should also occur after any severe weather or site modifications.

Proper Anchoring and Tie-Backs: Use wall ties or anchors to secure scaffolding to the structure, especially for tall or multi-level assemblies. This prevents tipping or swaying under wind or dynamic loads.

Train All Personnel: Ensure all workers are trained on assembly, usage, fall protection protocols, and emergency response procedures. Supervisors should be qualified to inspect and approve scaffold setups.

Maintain Clear Access: Do not obstruct ladders or platform paths. Keep materials organized and ensure emergency exits are accessible.

Use Edge Protection: Guardrails, midrails, and toe boards must be installed on all open sides of elevated platforms to prevent falls and falling objects.

Weather Awareness: Avoid using scaffolding during high winds, storms, or icy conditions. Always cover or secure materials in bad weather. wear PPE (hard hats, harnesses, gloves)

Conclusion

H-frame scaffolding continues to be a go-to solution for construction professionals worldwide. Its strength, simplicity, and safety make it ideal for both everyday tasks and specialized applications. Whether you’re managing a high-rise project, maintaining industrial equipment, or staging an event, H Frame scaffolding offers a dependable and efficient solution.

FAQ

What materials are commonly used in H-Frame scaffolding?

H Frame scaffolding is typically made from galvanized steel or aluminum. Galvanized steel is favored for its high load-bearing capacity, corrosion resistance, and long service life, especially in outdoor or humid environments. Aluminum, while lighter, is also strong and offers easy handling and faster setup. Some systems incorporate hot-dip galvanization or powder coating for added protection.

How does H Frame scaffolding differ from Ringlock or Cuplock systems?

H Frame scaffolding consists of rigid, pre-welded vertical frames (forming the “H” shape) connected by horizontal and diagonal braces. It is ideal for repetitive structures and fast setups. In contrast, Ringlock and Cuplock systems are modular and feature node-based connections—allowing for more complex geometries, custom configurations, and higher flexibility in challenging or irregular construction environments.

What safety features are built into H Frame scaffolding?

Standard safety features include continuous guardrails, midrails, toe boards to prevent tools from falling, anti-slip platforms for stable footing, and locking mechanisms such as snap pins or clamps that secure components. Many systems also incorporate integrated ladder access and use of high-visibility paint or labeling for on-site safety compliance.

Can H Frame scaffolding be reused for multiple projects?

Yes, H Frame scaffolding is designed for durability and reusability. With regular maintenance—such as checking welds, cleaning connectors, and protecting surfaces from rust or impact damage—it can be safely used across numerous projects. The modular nature of the system makes it easy to transport and store.

What are the most common types of H Frame scaffolds used in commercial projects?

Walk-through frames are frequently used in facade and renovation projects for unrestricted movement along building exteriors. Double-width frames are popular in large-scale commercial work due to their spacious working platforms, accommodating more workers and materials simultaneously. Ladder frames are also common in multi-story applications where vertical access is frequent.