- 388 Dongwu South Road, Suzhou City, P.R.China

- info@apacscaffold.com

- 0086-512-66700084

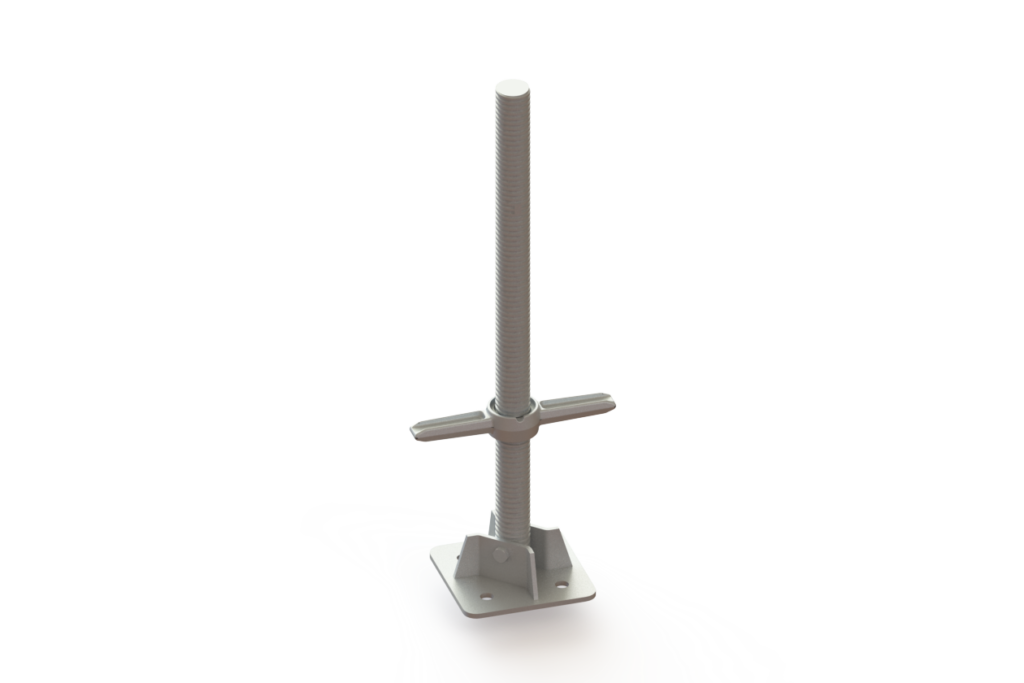

A scaffold base jack is an essential component of scaffolding systems, designed to provide a stable and adjustable foundation for scaffolding structures. It typically consists of a threaded bar, a base plate, and a jack nut, which allows precise height adjustments to level the scaffold on uneven or sloped surfaces.

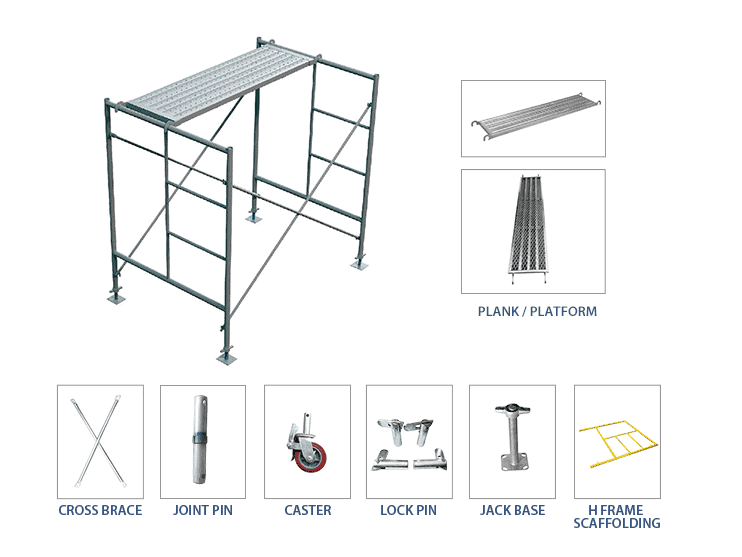

We proudly offer three meticulously designed types of scaffold base jacks, each crafted to address unique scaffolding requirements with precision and versatility, ensuring optimal performance and adaptability across various construction and industrial applications.

Provides a stable and adjustable foundation for leveling scaffolding on uneven surfaces.

Features a pivoting base plate that adjusts to sloped or irregular ground.

Designed with a U-shaped head to support beams or girders in formwork and shoring systems.

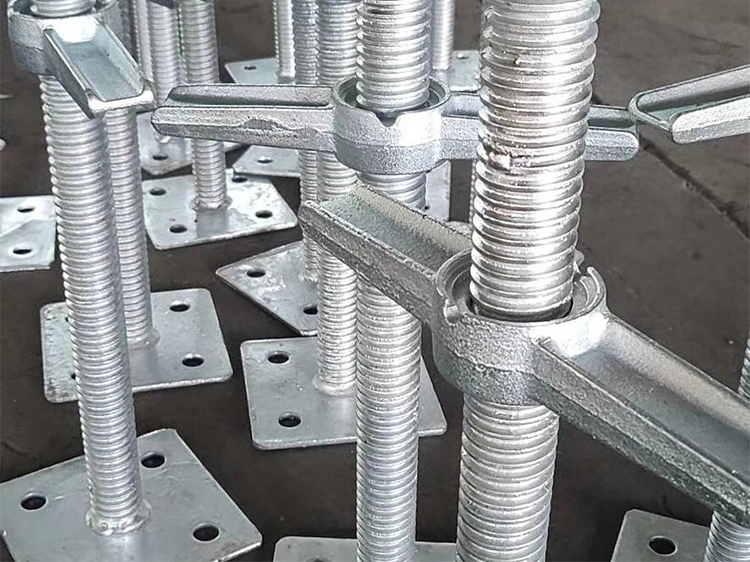

Our scaffold base jacks are constructed from Q235 and Q345 carbon steel, ensuring that they are both strong and durable. These high-quality materials help withstand heavy loads and provide excellent stability, even in challenging conditions. Additionally, the galvanized surface treatment protects against corrosion, extending the life of the base jack and reducing maintenance costs over time.

Our scaffold base jacks feature an adjustable length from 100mm to 1000mm, allowing you to easily adjust the height of your scaffolding to match the requirements of your project. This adjustability, coupled with a simple threaded design and cast nut system, ensures that the jacks are quick and easy to install, saving you valuable time during setup.

We understand that every construction project has unique requirements. That’s why we offer customized scaffold base jacks tailored to your specific project needs. Whether you need different sizes, finishes, or other adjustments, we can provide a solution that meets your exact specifications, ensuring that you get the most out of our products.

A base jack in scaffolding is a vital component used to stabilize and level the base of a scaffolding system. It is an adjustable support unit that provides a secure foundation for scaffolding frames, especially on uneven or unstable ground. Typically, the base jack consists of a threaded stem, a base plate, and a jack nut. The threaded stem allows for precise height adjustments, which ensures that the scaffolding is level and secure.

Base jacks are essential for distributing the weight of the scaffold structure and its load evenly across the ground. They are commonly used in various scaffolding systems, including frame scaffolds, ringlock, cuplock, kwikstage, and tube and clamp systems. By ensuring a stable and level setup, base jacks enhance the safety and durability of the scaffolding, reducing the risk of instability or collapse during construction and maintenance tasks.

Using a scaffold base jack is a straightforward process that ensures the stability and level alignment of your scaffolding system, even on uneven surfaces. Here's a step-by-step guide on how to properly use a scaffold base jack:

By following these simple steps, you can easily install and adjust your scaffold base jacks for a secure and level scaffolding setup, ensuring both stability and safety on your construction or maintenance site.

The load capacity of a scaffold base jack can vary based on several factors such as the type of base jack, its material construction, and the specific design. However, a general range for the load capacity of standard scaffold base jacks is:

Material: Most base jacks are made of high-strength steel (e.g., Q235, Q345 carbon steel), which ensures they can handle heavy loads. Some may have galvanized finishes for corrosion resistance, maintaining strength under harsh environmental conditions.

Design and Structure: The presence of additional support features, such as stiffeners or reinforced base plates, can increase the load capacity, making them suitable for more demanding scaffolding systems.

Scaffolding System: The overall load capacity of the scaffold system can impact the load that the base jack needs to support. Systems like Ringlock, Kwikstage, or Cuplock may require higher-capacity base jacks, while more lightweight systems may need base jacks with lower capacity.

Adjustment Mechanism: The threaded stem and the way it is constructed also play a role in the capacity, with thicker, more robust threads offering higher strength.

Load Distribution: It’s important to ensure that the load is evenly distributed across all the base jacks used in a scaffold system. Uneven weight distribution can reduce the load-bearing capacity and increase the risk of failure.

Safety Factor: Base jacks are typically designed with a safety margin to prevent overloading. Always ensure that the load applied does not exceed the recommended load capacity for the specific base jack model you are using.

In summary, while typical scaffold base jacks have a load capacity ranging from 2 to 6 tons, it’s essential to consult the product's technical specifications to confirm the exact capacity for the base jack you are using, considering your specific application.

For additional resources and detailed information about our scaffolding systems, visit our DOWNLOAD page.

Our scaffold base jacks are versatile and suitable for various scaffolding systems, including:

They provide a stable foundation, precise height adjustments, and reliable support, making them ideal for construction, maintenance, industrial projects, and custom scaffolding setups.

WhatsApp us