Introduction

Formwork is far more than a temporary mould for fresh concrete—it’s the backbone of any cast-in-place structure, dictating geometry, finish quality, jobsite safety and overall project economics. Whether you’re erecting a high-rise core, pouring a residential basement wall or crafting a complex architectural feature, choosing the right formwork system determines how quickly, safely and cost-effectively you’ll achieve the desired result. In this guide, we’ll explore:

- What formwork is and why it matters

- Main formwork types used worldwide

- Key benefits and trade-offs of each system

- Best practices for selection, installation, and maintenance

By the end, you’ll have the insights you need to align your next concrete project with the optimal formwork solution.

What Is Formwork and Why It Matters

Formwork refers to the temporary structures—panels, supports and accessories—that contain fresh concrete until it develops sufficient strength to support itself and any imposed loads. Its four core functions are:

- Shaping: Determines final geometry (slabs, beams, columns, walls).

- Supporting: Resists hydrostatic pressure, dead loads and live loads during placement.

- Finishing: Influences the surface texture and dimensional accuracy of the hardened concrete.

- Access & Safety: Often incorporates working platforms, guardrails and lifting points to safeguard crews.

Because formwork can account for up to 30% of total project cost and 60% of concrete-related labor, optimizing your formwork strategy is paramount for on-time delivery, budget control and long-term performance.

5 Main Types of Formwork

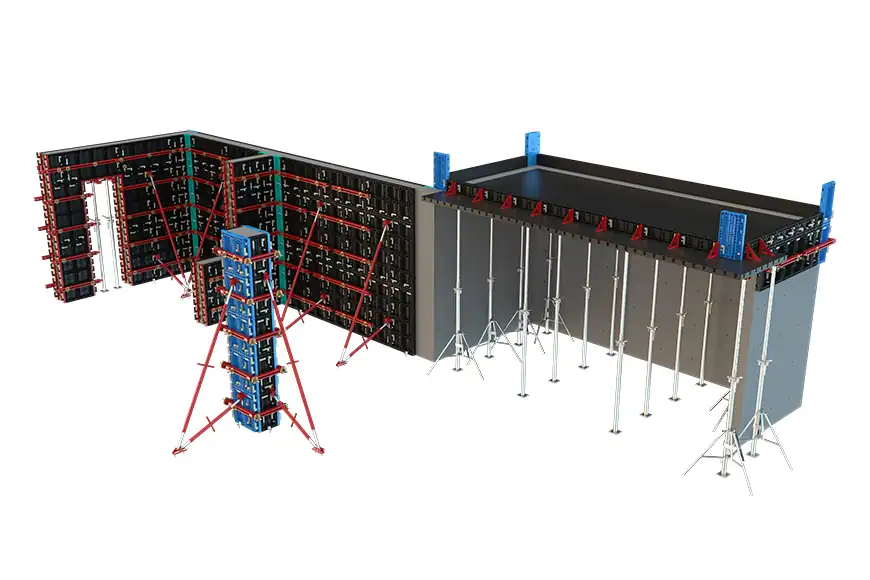

Engineered (System) Formwork

Definition & Components

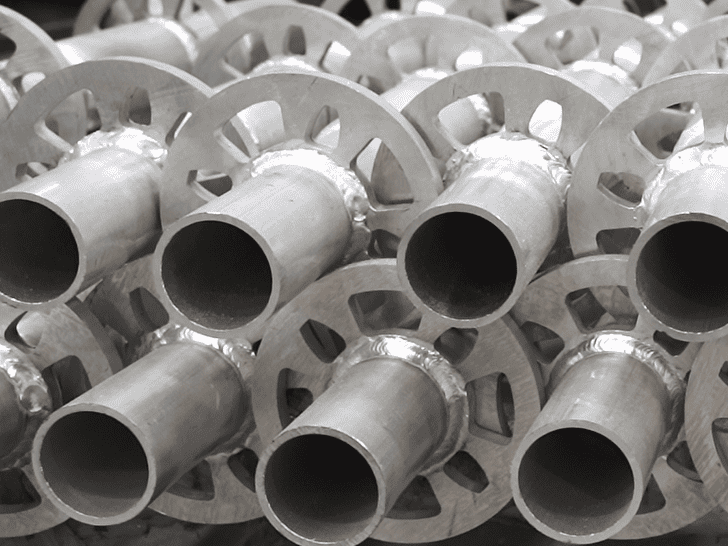

Engineered formwork—often called “system” formwork—consists of prefabricated panels, frames and standardized fittings manufactured from steel or aluminum. These panels are designed with precision-machined edges and integrated connection points (clamps, bolts or quick-release clips), allowing them to interlock quickly without on-site cutting or custom carpentry.

Key Elements

Facing Panels: Smooth steel or aluminum sheets that define the concrete surface.

Framing Rails: Rigid box-section members that support the panels and transfer load to the props.

Connection Hardware: Factory-engineered clamps, wedges or pins that lock panels together with consistent pressure.

Bracing & Props: Adjustable shores, walers and cross-braces that secure the system and resist hydrostatic forces.

Advantages:

- Rapid assembly and dismantling

- Exceptional dimensional precision, yielding smooth, uniform finishes

- High reuse life (100–200 pours with proper care)

Considerations:

- Higher initial investment relative to timber

- Requires space for cleaning, storage and handling

Ideal for repetitive pours in high-rise cores, flat slabs and tunnel linings where cycle time and finish quality are critical.

Timber and Plywood Formwork

Definition & Components

Timber and plywood formwork is the traditional method of casting concrete, constructed on-site by skilled carpenters using solid timber members (studs, joists, battens) combined with plywood sheets as facing. The timber frame provides structural support, while the plywood delivers a relatively smooth concrete surface.

Key Elements

Timber Framing: Vertical studs and horizontal walers made from sawn lumber, sized to carry wet-concrete loads.

Plywood Facing: Factory-manufactured sheets (typically 12–18 mm thick) nailed or screwed onto the frame to form the contact surface.

Fasteners & Bracing: Nails, screws or tie–rod assemblies secure the facing to the frame; diagonal braces and shores hold the assembly plumb and straight.

Edge Strips & Fillets: Narrow timber battens used to seal joints and create chamfers or rounded edges.

Advantages:

- Low upfront material cost

- Easily adapted to irregular or curved shapes

- Repairable with locally available carpentry skills

Considerations:

- Limited reuse (10–15 cycles) before panels warp or delaminate

- Inconsistent finish quality and dimensional stability

- Greater labor input for cutting, fitting and nailing

Often selected for one-off architectural features, renovation works and small-scale projects.

Insulated Concrete Formwork (ICF)

Definition & Components

Insulated Concrete Forms (ICF) are hollow, interlocking blocks or panels made of expanded polystyrene (EPS), polyurethane or similar insulating materials. Once stacked and braced, they create a continuous form into which concrete is poured. After curing, the forms remain as permanent insulation on both sides of the wall.

Key Elements

Insulating Panels/Blocks: EPS or polyurethane units with built-in webs or ribs to hold rebar and maintain cavity width.

Alignment Connectors: Plastic or metal ties that lock the two wythes of insulation together and set rebar spacing.

Reinforcement Cage: Steel rebar installed within the form cavity to meet structural requirements.

Bracing & Leveling System: Adjustable shores and braces to keep forms plumb and aligned during pouring.

Advantages:

- Provides continuous thermal and acoustic insulation

- Speeds up installation and eliminates the need for stripping

- Improves airtightness and fire resistance

Considerations:

- Higher material cost and increased on-site storage volume

- Requires careful detailing at openings and penetrations

Best for energy-efficient residential walls, basements and low-rise commercial buildings aiming for green-building certification.

Plastic and Fiberglass (GRP) Formwork

Definition & Components

Plastic and fiberglass formwork systems use panels or modules made from high-density polyethylene (HDPE) or glass-reinforced polyester (GRP). These panels are often rib-stiffened or honeycombed internally for added strength, and interlock via corner keys, clips or tongue-and-groove joints to create a leak-tight mould.

Key Elements

Panel Shells: HDPE or GRP sheets molded into panels with built-in stiffeners.

Connection Mechanisms: Clips, clamps or keyed joints that align and seal panel edges.

Support Frames: Lightweight aluminum or steel frames that bear the wet concrete load.

Sealing Gaskets: Optional rubber or foam strips for high-precision joints in water-retaining structures.

Advantages:

- Lightweight handling reduces crane and labor time

- Excellent resistance to moisture, chemicals and abrasion

- Produces smooth, defect-free concrete surfaces

Considerations:

- Moderate reuse life (20–50 cycles)

- Higher purchase price than timber

Ideal for water-retaining structures, tunnels, curved architectural elements and repetitive pours in corrosive environments.

Stay-In-Place Metal Decking

Definition & Components

Stay-in-place metal decking consists of corrugated steel sheets laid across structural supports (beams or joists) that serve as both the formwork for fresh concrete slabs and as permanent tension reinforcement once the concrete cures. The decking profiles interlock laterally, creating a stable working platform and eliminating the need for temporary falsework under the slab.

Key Elements

Corrugated Deck Panels: Cold-formed steel sheets with ribbed profiles (e.g., fluted, trapezoidal) that lock together to span between supports.

Positive Interlock: Side and end laps are designed to prevent lateral displacement and ensure a continuous diaphragm.

Shear Stud Connectors (Optional): Welded studs or deformed bars can be attached through the decking into the slab to create a composite action with the supporting steel frame.

Edge Trim & Closure Plates: Perimeter and penetration details that seal the form and provide neat edges for finishing.

Advantages:

- Eliminates slab falsework, shortening cycle times

- Integrates with rebar to carry tensile forces

- Delivers consistent slab flatness and structural performance

Considerations:

- Coordination required between steel fabricator and concrete teams

- Added dead load to structural design

Widely used in multi-storey commercial buildings, parking garages and long-span floor systems where speed and flatness are priorities.

Key Benefits of the Right Formwork Choice

- Faster Project Delivery: Engineered systems and metal decking can cut pour cycles by up to 30%, accelerating overall schedules.

- Enhanced Safety: Factory-designed panels with integrated platforms and guardrails reduce fall hazards and site modifications.

- Cost Control: Although some systems have higher upfront costs, their high reuse rates and labor savings drive significant per-cycle savings.

- Superior Surface Quality: Precision-manufactured panels produce smooth, uniform finishes, minimizing grinding or patching.

- Resource Optimization: Modular sizing and just-in-time deliveries limit material waste, off-cuts and on-site storage needs.

Best Practices for Selecting and Using Formwork

- Align System to Project Needs:

- Repetitive, high-volume pours → Engineered or stay-in-place decking

- Irregular or bespoke shapes → Timber, plastic or GRP

- Energy-efficient envelope → Insulated concrete forms

- Repetitive, high-volume pours → Engineered or stay-in-place decking

- Involve Suppliers Early:

- Collaborate during design to optimize panel layouts, cut-lists and clash-free BIM coordination.

- Collaborate during design to optimize panel layouts, cut-lists and clash-free BIM coordination.

- Invest in Training:

- Ensure crews understand the specific assembly methods, safety protocols and maintenance routines.

- Ensure crews understand the specific assembly methods, safety protocols and maintenance routines.

- Enforce Rigorous Maintenance:

- Clean and inspect panels after each use; repair coatings and hardware promptly to maximize lifespan.

- Clean and inspect panels after each use; repair coatings and hardware promptly to maximize lifespan.

- Leverage Digital Tools:

- Use BIM and parametric modelling to simulate complex geometries, coordinate embeds and generate accurate material take-offs.

Conclusion

Formwork shapes more than just concrete—it shapes project performance, safety, quality and sustainability. By understanding the strengths and trade-offs of engineered, timber, insulated, plastic and decking systems—and by applying best practices in planning, procurement, training and upkeep—construction teams can deliver durable, high-performance structures that meet design intent, budget constraints and environmental goals.

FAQ

How long must formwork remain in place?

- Vertical elements (walls, columns): typically stripped after 24–48 hours, once concrete attains sufficient strength.

- Horizontal elements (slabs): often left for 7–14 days or until specified design strength is reached.

Which formwork type offers the highest reuse?

Engineered steel or aluminum panels, when well maintained, can last for 100–200 pours.

Can ICF contribute to green-building credits?

Yes. ICF’s permanent insulation and airtightness help earn points under schemes like LEED, BREEAM and other regional certifications.

Is plastic formwork strong enough for structural walls?

HDPE and GRP panels offer good strength and finish. For primary load-bearing walls, they can be used if designed to accommodate expected loads and embed requirements.

How do I decide between timber and engineered formwork?

Consider project scale, repetition and shape complexity: timber is cost-effective for small batches or unique shapes; engineered systems shine on large, repetitive pours where cycle speed and finish consistency are paramount.